Home >> Industries

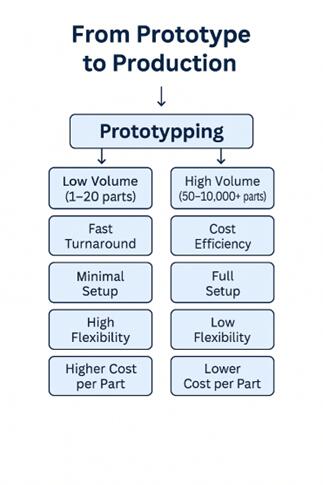

Understanding the distinction between prototyping and production runs is critical for cost efficiency, lead time planning, and design validation. Both serve different stages of a product’s lifecycle—and require tailored strategies.

CNC (Computer Numerical Control) machining is a popular method for creating prototypes due to its precision, speed, and ability to produce complex shapes with tight tolerances. It's a subtractive manufacturing process where a digital design is used to control a machine that removes material from a raw workpiece, resulting in a physical prototype.

Prototyping

Purpose:

To validate design, fit, function, and manufacturability before mass production. Prototyping is more flexible and allows for easy design changes, while production focuses on consistent, repeatable results.

Aspect | Details |

Volume | 1–20 parts (typically) |

Speed | Fast turnaround prioritized over cost |

Setup | Minimal setup, may use soft tooling or temporary fixturing |

Flexibility | Design changes are expected and easily implemented |

Inspection | Often includes full dimensional reports or CMM checks |

Cost per Part | Higher (due to setup not being amortized) |

Ideal For | Engineering validation, fit testing, proof-of-concept |

Production Runs

Purpose:

CNC production runs involve using Computer Numerical Control machines to manufacture parts or components in large quantities. This process relies on computer-controlled machines and pre-programmed instructions to achieve high precision, consistency, and efficiency in the production of parts.

Aspect | Details |

Volume | 50–10,000+ parts |

Speed | Optimized for cost and consistency |

Setup | Full production tooling and jigs; automated workholding |

Flexibility | Design changes costly; tight version control required |

Inspection | Sampling-based QC (SPC, visual, in-line) |

Cost per Part | Lower (setup costs spread across parts) |

Ideal For | Market release, inventory, commercial deployment |

Key Takeaway

Prototyping is about speed and feedback.

Production is about repeatability and efficiency.

Using both strategically ensures faster development cycles and reliable part delivery.

In summary, CNC machining provides a versatile and accurate method for both prototyping and production, with the choice depending on the specific needs of the project and the stage of product development.

Not sure whether your project should be treated as a prototype or production run?

Send us your drawings and target volume.

We’ll help you choose the right CNC strategy—and avoid costly missteps during scale-up.

Previous: None