How Rollyu Precision Delivers Zero-Defect Components for Global Industries

When you hold a precision-machined part from Rollyu Precision in your hand, you’re holding the product of decades of experience, rigorous processes, and the unwavering commitment of skilled engineers, well-trained workers, and seasoned machinists.

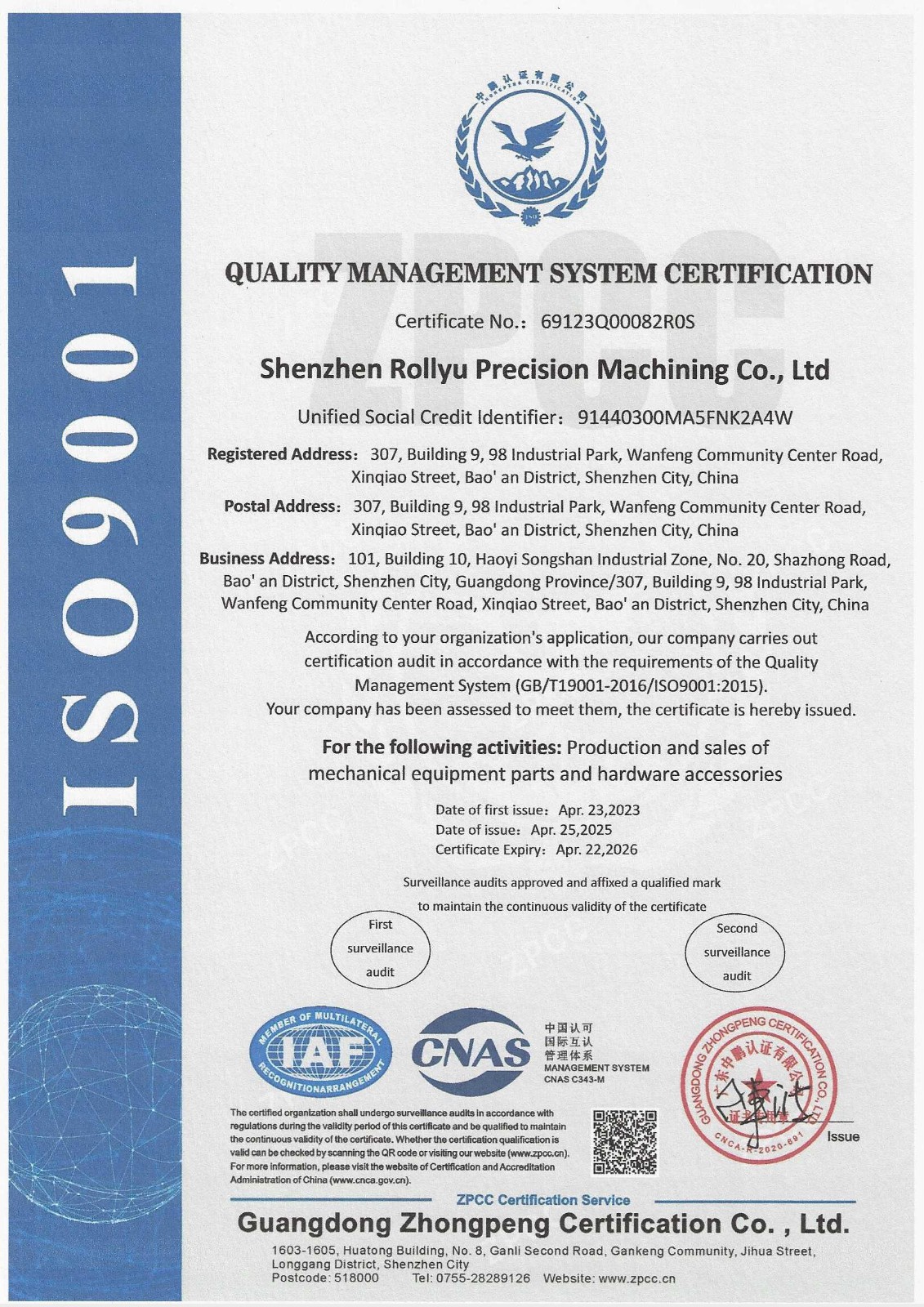

At Rollyu, precision is not a slogan—it is the essence of our work and our promise to every customer we serve. With ISO 9001:2015 and ISO 13485:2016 certifications, we stand behind the quality of each component that leaves our facility, ensuring it performs exactly as intended, in the most demanding applications.

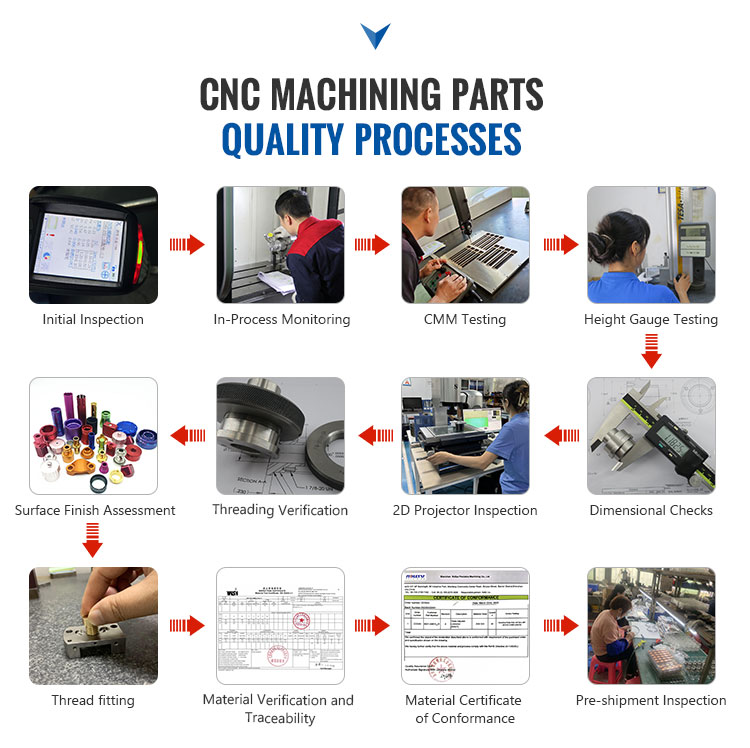

From the first consultation to final delivery, Rollyu Precision has designed a culture and a workflow that focus on one goal: zero-defect parts. This is not achieved through a single step or a one-time effort—it is the result of a relentless, structured quality management system and our dedication to what we call 6×100%:

✅ 100% Incoming Materials Inspection

✅ 100% Dimension Achievement

✅ 100% Meeting Surface Finish Standards

✅ 100% Pre-Shipment Inspection

✅ 100% On-Time Delivery

✅ 100% Personalized Customer Support

Every step is intentional, carefully planned, and monitored to ensure that your parts consistently meet—and often exceed—expectations.

A Culture of Quality Rooted in Skilled People

While modern machinery, inspection equipment, and digital workflows play essential roles in our operations, the true foundation of Rollyu Precision’s reputation is our people.

Our engineers bring years of advanced technical expertise to each project. They review specifications, identify challenges early, and optimize machining strategies to maximize precision and efficiency.

Our machinists are masters of their trade, experienced in handling a wide spectrum of materials and component geometries—from the simplest brackets to the most complex, multi-axis contours. They are trained not only to operate the latest CNC technology but to understand why each operation matters to the part’s function, strength, and appearance.

And our quality team is relentless. They are the ones who ensure no corners are cut and no detail overlooked. They are the last line of defense against any imperfection that could compromise your project.

Performing 6×100%: The Backbone of Our Zero-Defect Promise

1️⃣ 100% Incoming Materials Inspection

Quality begins before a single chip is cut. Every batch of raw material entering our facility undergoes a comprehensive inspection. Certificates of compliance are verified, materials are cross-checked against the purchase order, and physical properties—such as alloy composition, hardness, and dimensional compliance—are confirmed through sampling and testing.

This prevents costly downstream issues and guarantees that your parts are manufactured from authentic, certified materials with full traceability.

2️⃣ 100% Dimension Achievement

Tight tolerances are a hallmark of our work. Whether it’s a 0.005 mm tolerance on a precision bore or a ±0.01 mm requirement for a complex contour, our machinists and inspectors measure each critical dimension using calibrated instruments, such as:

Coordinate Measuring Machines (CMM)

Digital micrometers and calipers

Height gauges and depth gauges

Thread gauges and plug gauges

No part proceeds without complete dimensional verification.

3️⃣ 100% Meet Surface Finish Standards

A part’s performance often depends as much on its surface finish as its size. Many of our components require specific Ra values or cosmetic standards, particularly in medical, semiconductor, and optical applications.

We deploy surface roughness testers to verify that each part meets the required finish criteria—whether that is a satin anodized surface, a mirror-polished edge, or a matte bead-blasted texture.

4️⃣ 100% Pre-Shipment Inspection

Before parts are packed, our inspectors conduct a final comprehensive check. This includes:

Dimensional revalidation of critical features

Verification of labeling and packaging requirements

Confirmation of any special documentation (e.g., material certs, first article inspection reports, or custom inspection records)

Only after passing this rigorous checkpoint do parts proceed to shipping.

5️⃣ 100% On-Time Delivery

Precision doesn’t only apply to the parts themselves—it also applies to schedules. We understand that our customers depend on punctual deliveries to keep their production lines running.

Our production planning system and real-time tracking ensure that your orders are fulfilled as promised, every time.

6️⃣ 100% Personalized Customer Support

At Rollyu, every client is a partner. Whether you have a technical question, need help selecting the right material, or require urgent status updates, our team is responsive and solution-focused.

The Standards We Uphold: ISO9001:2015 and ISO13485:2016

Rollyu Precision’s quality management system is certified to ISO9001:2015 and ISO13485:2016 standards.

ISO9001:2015 defines international best practices for a quality management system. Our certification confirms that we:

Consistently deliver products that meet customer and regulatory requirements

Continuously improve our processes and systems

Demonstrate strong leadership commitment to quality

ISO13485:2016 applies specifically to medical device manufacturing. It requires an even higher standard of process control, traceability, and risk management to ensure patient safety.

By investing in these certifications, Rollyu demonstrates a commitment to the highest level of accountability and quality assurance, not only for medical components but across every industry we serve.

Serving as an Outstanding Business Partner in Every Phase

The path to zero-defect manufacturing starts long before production.

✅ Thorough, Responsible Quoting

Every project begins with a carefully prepared quotation. Our estimators and engineers collaborate to analyze your drawings, assess tolerances, material requirements, and surface treatments, and develop a realistic, transparent quote.

By identifying potential challenges at this stage—such as hard-to-machine geometries, specialized finishing, or material lead times—we prevent surprises later in the process.

✅ Proactive Technical Consultation

Our engineering team works directly with you to confirm feasibility, offer DFM (Design for Manufacturability) suggestions, and optimize production methods.

This upfront collaboration ensures that your parts are produced efficiently and with the right balance of performance and cost.

Delivering Precision Machining that Meets the Most Demanding Specifications

At Rollyu, we specialize in complex, tight-tolerance machining that many shops consider too challenging.

Whether your project requires 3-axis, 4-axis, or full 5-axis milling, our equipment and programming expertise enable us to produce intricate geometries with exceptional accuracy.

We routinely machine parts that integrate multiple features in a single setup—reducing stack-up error and ensuring consistent quality.

Our capabilities include:

Ultra-precise bores and tapped holes

Complex pocketing and contouring

Thin-wall features

Tight-tolerance mating surfaces

CNC turning with live tooling

A Comprehensive Approach to Materials and Finishes

Selecting the right material is essential for any project’s success. Rollyu maintains trusted supply relationships and deep experience in sourcing and machining a wide spectrum of materials:

✅ Metals

Aluminum alloys (6061, 7075, 5052)

Stainless steel (303, 304, 316, 17-4)

Alloy steels

Titanium

Kovar, Inconel, Invar, Haynes 188, Alloy 46

✅ Plastics & Polymers

POM (Delrin)

PTFE

PEEK

Ultem

✅ Specialty Materials

Closed-cell foams

Graphite composites

Our machinists are trained to adapt feeds, speeds, and tooling strategies to the unique characteristics of each material—whether it’s controlling heat distortion in thin titanium parts or managing chip removal in gummy plastics.

Finishing Expertise

Many parts require advanced finishing processes to meet performance or cosmetic requirements:

Anodizing (Type II and III)

Powder coating

Plating (zinc, nickel, tin, gold)

Electropolishing

Passivation

Lapping and honing

Our team manages finishing workflows to ensure every part achieves the desired appearance, protection, and dimensional consistency.

Quality Management System (QMS): The Framework Behind Every Perfect Part

Behind our zero-defect culture stands an integrated QMS designed to guarantee traceability, accountability, and improvement.

Inspection and Metrology Capabilities

Our inspectors utilize:

Coordinate Measuring Machines (CMM) for 3D measurement of complex geometries

Optical comparators and profile projectors for visual and dimensional verification

Surface roughness testers to confirm Ra specifications

Hardness testers for material property validation

Thread gauges, pin gauges, and micrometers for precision feature checks

Every instrument is calibrated regularly, and all inspection data are recorded for traceability.

Process Controls and Continuous Improvement

We conduct internal audits, corrective action reviews, and regular training sessions. This allows us to spot trends, identify root causes, and implement preventive measures proactively.

Our QMS is not static—it evolves continually to reflect customer needs, regulatory changes, and new technology.

Why Rollyu Precision?

When you choose Rollyu, you’re not simply purchasing parts—you’re investing in a partnership defined by:

✅ Zero-defect results

✅ On-time delivery

✅ Responsive, consultative support

✅ Full traceability and accountability

✅ A commitment to continuous improvement

From medical devices to aerospace assemblies and photonics enclosures, our parts perform reliably in applications where failure is not an option.

Here are our quality certificates:

Looking Ahead: Sustaining Quality in an Evolving Manufacturing Landscape

Industries are evolving faster than ever. As technologies advance and tolerances tighten, the stakes for reliable, precise parts grow even higher.

Rollyu Precision will continue to invest in:

Advanced machining centers

with higher spindle speeds and better thermal stability

Automated inspection systems

to accelerate validation without compromising accuracy

Training programs

to keep our team at the forefront of modern manufacturing

Sustainability initiatives

to ensure responsible use of materials and energy

These investments strengthen our promise: every part you receive from Rollyu Precision will be precise, accurate, and built to exceed expectations.

Ready to Experience the Difference?

If you are searching for a machining partner dedicated to excellence, accountability, and zero-defect manufacturing, Rollyu Precision is here to support you.

Reach out to our team to discuss your next project. Together, we can design and deliver components that drive your success—piece by piece, part by part.