Home >> Industries

Precision Machined & Investment-Cast Components for Medical, Surgical, and Dental Devices

When lives depend on the accuracy of a single micron, you need a manufacturing partner that treats every part as mission-critical. Rollyu Precision delivers investment castings and CNC-machined components that power today’s most advanced medical diagnostics, surgical robotics, patient-handling systems, and dental equipment. Backed by ISO 9001 and ISO 13485 certifications, we combine world-class quality assurance with flexible production volumes—so you get flawless parts, on time, every time.

Why OEMs Choose Rollyu for Medical Device Components

Ultra-tight tolerances: Five-axis machining, Swiss turning, and high-pressure investment casting hold critical dimensions to ±0.005 mm.

Medical-grade materials: 17-4 PH stainless, Ti-6Al-4V, cobalt chrome, PEEK, and other biocompatible alloys—all traceable to mill certificates.

Sterile-ready finishes: Electropolishing, passivation, laser marking, and Class 10 000 clean-room packaging ensure immediate integration into your production line.

Regulatory alignment: Full DHR/DMR documentation, lot tracking, and validation protocols simplify FDA, MDR, and CFDA submissions.

Core Markets & Typical Components

Diagnostic & Imaging Equipment

Pump housings, sensor mounts, RF-shielded enclosures

X-ray collimator plates, MRI gradient coil end caps

Fluid-handling manifolds with burr-free micro passages

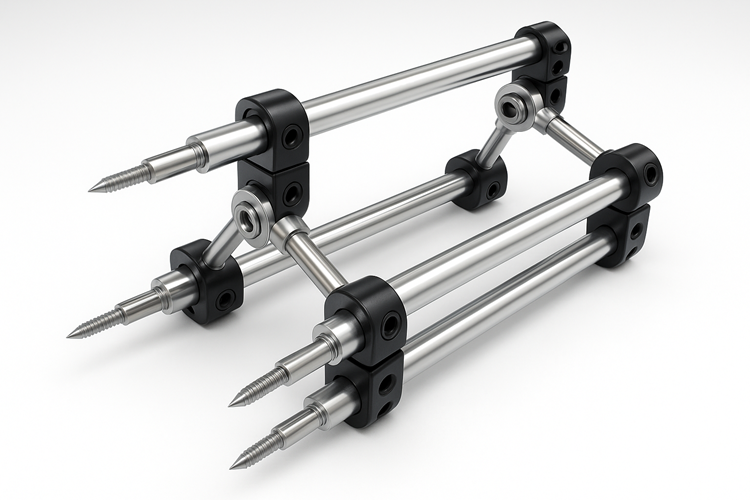

Surgical & Patient-Handling Systems

Arthroscopic shaver hubs, laparoscopic trocar sleeves

Precision drive shafts, valve seats, and flange adapters

Lightweight aluminum castings for mobile operating tables

Medical & Surgical Robotics

Robotic arm joints, harmonic-drive housings, cable output ports

Titanium end effectors: graspers, needle drivers, micro scalpels

Control-console heat sinks and EMI covers machined from 6061-T6

Implantable & Orthopedic Devices

Porous titanium fusion cages, hip stem trial components

Cannulated bone screws, custom trauma plates

Cobalt-chrome femoral knee blanks ready for polishing

Dental Equipment & Instruments

High-speed handpiece bodies, contra-angle gear trains

Implant abutments, surgical guides, disposable burs

Autoclavable syringe tips, ultrasonic scaler horns

Manufacturing Toolbox

Capability | Benefit for Medical OEMs |

Investment Casting (lost wax) | Near-net geometry cuts secondary machining and material waste. |

5-Axis CNC Milling & Turning | Complex contours and micro-features in a single setup = perfect repeatability. |

Wire EDM & Micro-Drilling | Burr-free slots and through-holes as small as Ø0.15 mm. |

Laser Welding & Marking | Hermetic seals with minimal HAZ; UDI and lot codes that survive autoclaves. |

In-Process Metrology | Inline CMM probing and optical inspection for 100 % dimensional verification. |

End-to-End Quality Assurance

Material certification & biocompatibility testing to ASTM F136, ISO 10993, and USP Class VI.

Process validation (IQ, OQ, PQ) and statistical process control to maintain CpK > 1.67.

Environmental & sterilization simulations (ETO, gamma, steam) confirm coating and mechanical integrity.

Full traceability—from raw billet to final shipment—stored securely for 15 years.

Innovation Drivers We Support

Miniaturization: Lighter, smaller pump impellers and sensor housings for wearable or handheld diagnostics.

Smart Surgery: Embedded channels and mounts for fiber-optic sensors in next-generation robotic wrists.

Sustainable Healthcare: Material-efficient investment castings and recyclable titanium scrap reclamation programs.

Ready to Accelerate Your Medical Device Program?

Whether you need prototype quantities for a new laparoscopic tool or annual volumes for Class III implants, Rollyu Precision has the expertise, capacity, and certifications to deliver.

Let’s turn your CAD model into a life-saving reality.