Home >> Industries

Precision CNC Machining for Food-Grade Equipment: Building Clean, Durable, High-Performance Parts

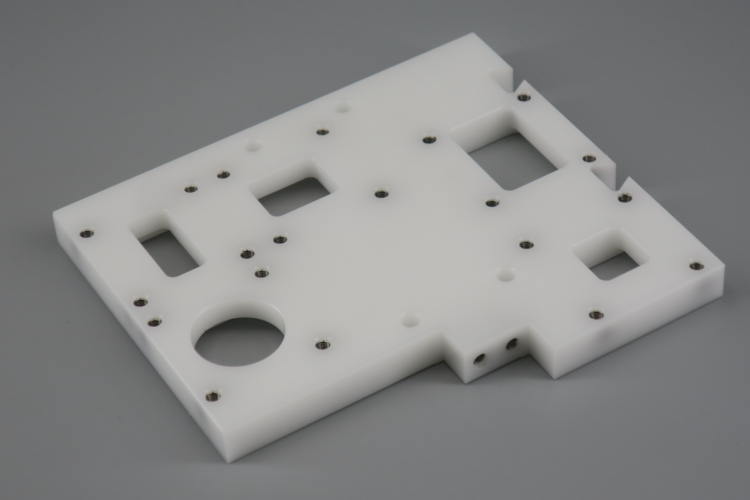

When you're designing equipment that blends, cuts, cooks, or packages the food we eat every day, every component must be hygienic, hard-wearing, and dimensionally perfect. Precision CNC (Computer Numerical Control) machining delivers that reliability, turning food-safe metals and polymers into parts that survive caustic wash-downs, thermal cycling, and nonstop production shifts—while still meeting strict food grade guidelines.

Why CNC Machining Is Indispensable to Modern Food Processing

Micro-level accuracy. Tolerances down to ±0.01 mm keep blades aligned, filling nozzles leak-free, and sealing jaws airtight—directly impacting yield and shelf life.

Repeatability at scale. Once a program is dialed in, multi-axis CNC machines replicate complex geometries thousands of times with near-zero deviation, perfect for volume production.

Material versatility. From corrosion-resistant 316L stainless to ultra-low-friction UHMW-PE, CNC processes them all without compromising surface finish.

Rapid prototyping & changeovers. Need to tweak a slicer blade profile or increase throughput on a dosing valve? Adjust the CAM file, not the tooling—a critical advantage in a market that prizes agility.

Mission-Critical Components We Machine

Processing Step | CNC-Made Parts | Why They Matter |

Mixing & Blending | Blades, agitators, drive shafts | Uniform particle distribution and reduced batch times hinge on perfectly balanced impellers and vibration-free shafts. |

Slicing, Dicing, Cutting | High-carbon stainless knives, guides, pushers | Razor-sharp edges and precise guides minimize product waste and ensure consistent portioning. |

Conveying & Transfer | Hardened sprockets, gears, rollers | Exact tooth profiles eliminate belt slippage; hard-anodized rollers stand up to sugary or acidic residues. |

Filling & Packaging | Dosing nozzles, sealing jaws | Close-tolerance bores prevent drips; mirror-polished jaws create hermetic seals that extend shelf life. |

Heating & Cooling | Heat-exchanger plates, fins | Uniform wall thickness and tight fit-up promote efficient thermal transfer during pasteurization or chilling. |

Grinding & Milling | Interlocking grinding discs | Even wear patterns produce a consistent granule size, critical for flavor and texture control. |

Dispensing & Dosing | Valve bodies, metering pistons | Lapped surfaces and FDA-compliant O-ring grooves guarantee drop-in, drip-free performance. |

Materials That Make the Grade

316/304 Stainless Steel – Premier choice for direct food contact thanks to corrosion resistance, cleanability, and non-reactivity.

UHMW-PE & PEEK – Low-friction, self-lubricating polymers that reduce contamination risks in bearings and wear strips.

Aluminum (hard-coat anodized) – Lightweight, ideal for non-contact frames or motor housings; protective finish prevents oxidation.

Design & Manufacturing Best Practices for Food Equipment

Hygienic Geometry

Smooth radii, no blind pockets, full weld accessibility. This prevents bacterial harborage and speeds CIP (clean-in-place) cycles.

Surface Finishing

32 µin Ra or better on contact surfaces. CNC polishing and electropolishing cut biofilm risk to nearly zero.

Chemical & Thermal Endurance

Parts must survive caustic detergents at 82 °C wash-down, acid rinses, and blast freezing—often in the same shift.

Traceability & Documentation

Full material certs, lot numbers, and machining logs enable rapid root-cause analysis should a recall ever occur.

Compliance You Can Count On

Food grade material approvals

ISO 9001- and ISO 13485-certified processes

Bring Your Next Food-Equipment Project to Life

From high-output mayonnaise mixers to precision coffee-pod fillers, Rollyu Precision machines the parts that keep production lines running cleanly and efficiently. Tap into our multi-axis CNC cells, in-house passivation, and 100 % inspection program—and get components that meet every spec on the first delivery.

Let's talk drawings, lead times, and compliance today. info@rymachining.com

Previous: Precision Parts for Lighting