Home >> Industries

Precision CNC Machining for Agriculture: Powering Smarter, Stronger Farm Equipment

When a modern combine rolls across a field or a seed drill places kernels with millimetre-level accuracy, it is the hidden, precision-machined components inside that keep every pass efficient and profitable. From rugged tractor drivetrains to ultra-accurate spray nozzles, today’s agricultural machinery depends on CNC-crafted parts that can survive mud, chemicals, vibration and non-stop workloads—while still meeting ever-tighter sustainability targets.

Below you’ll find an overview—optimised for search and written like a human, not a robot—of the key components, materials and manufacturing practices that shape next-generation farming.

1 | Tractor Powertrains: Where Reliability Begins

Engine internals: Pistons, crankshafts and bearings machined to micro-level tolerances deliver consistent horsepower and longer service intervals.

Transmission gears: Precision-cut tooth profiles guarantee smooth shifting even under high torque, reducing operator fatigue and fuel use.

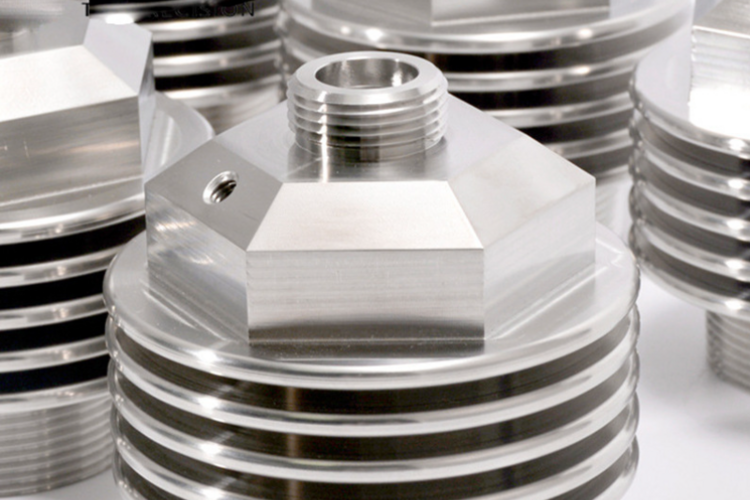

Hydraulic cores: Pumps, spools and valve blocks hold tight clearances so loaders, mowers and planters react instantly to fingertip controls.

2 | Soil Cultivation: Cutting, Turning, Loosening

Plough shares & tines: Custom-profiled blades slice through compacted earth while maintaining edge hardness that resists abrasion.

Disc harrow plates: Balanced, high-carbon discs conquer crop residue without chatter, creating the ideal seedbed.

3 | Seeding & Planting: Every Seed Counts

Accurate planting is the foundation of uniform emergence and record yields.

Metering wheels & vacuum disks: CNC-milled pockets singulate seed varieties from canola to corn at prescribed populations.

Coulters & opener blades: Hardened edges maintain depth control season after season, protecting germination rates.

Seed tubes & guides: Smooth-bore polymer tubes minimise bounce so seeds land exactly where agronomists planned.

4 | Harvesting: Clean Cuts, Minimal Loss

Combine knives & chopper blades: Laser-sharpened edges slice stalks neatly, reducing shatter and fuel draw.

Threshing cylinders: Perfectly concentric bars separate grain from straw with fewer cracked kernels.

5 | Post-Harvest & Processing

Grain auger flights: Precision-formed screw blades move cereals gently, preserving grain quality.

Sorters & graders: Machined rails and gates route produce by size and weight, protecting profit margins.

6 | Spraying & Application: Precision Chemistry

Nozzles: Orifice diameters held to ±0.01 mm create droplet spectra that maximise coverage and minimise drift.

Pump housings & valve bodies: Corrosion-resistant stainless and engineered plastics endure aggressive fertilisers and pesticides without swelling or pitting.

The Materials That Withstand Field Extremes

Material | Why It Excels on the Farm |

316/304 Stainless Steel | High corrosion resistance against fertilisers, manure acids and weather exposure. |

Heat-Treated Alloy Steels | Superior wear resistance for blades, gears and shafts that take constant impact. |

Aluminium Alloys | Lightweight strength ideal for booms and covers—reduces equipment mass and fuel consumption. |

UHMW-PE & Advanced Composites | Self-lubricating, non-stick surfaces perfect for seed tubes and grain handling parts. |

How Precision Is Built In

Five-Axis CNC Machining – Complex geometries and tight tolerances in a single set-up mean fewer alignment errors and faster deliveries.

Laser and Water-Jet Cutting – Creates burr-free edges on wear plates and shields, ready for immediate assembly.

Robotic Automation – Ensures repeatability for high-volume parts such as sprockets and couplings, keeping costs under control.

Stress & Fatigue Testing – Simulated duty cycles verify components won’t fail when farmers can least afford downtime.

Surface Treatments – Hard chrome, nitriding and powder-coat finishes extend lifespan and resist soil abrasion.

Tomorrow’s Trends: Smart & Sustainable

Sensor-Integrated Parts: Machined housings with embedded IoT chips provide real-time data on temperature, vibration and wear.

Eco-Focused Design: Weight-reduced components cut diesel consumption, while precision dosing nozzles slash fertiliser runoff.

Additive + Subtractive Hybrid: Combining 3-D printed features with CNC finishing unlocks lighter, stronger shapes impossible just a decade ago.

Ready to Strengthen Your Next Agriculture Project?

Rollyu Precision has spent 15 + years machining parts that push yields higher and operating costs lower. If you need prototype seed meters, high-volume auger flights or anything in between, our ISO-certified team is here to help.

Talk drawings, lead times and field-tested quality today.