Home >> Industries

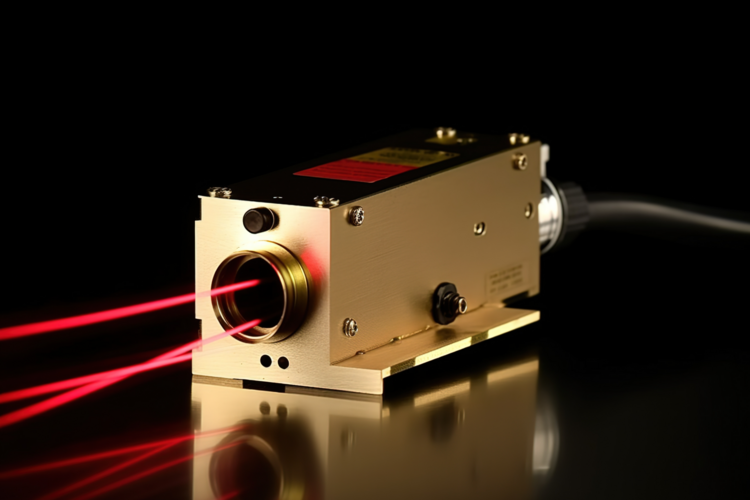

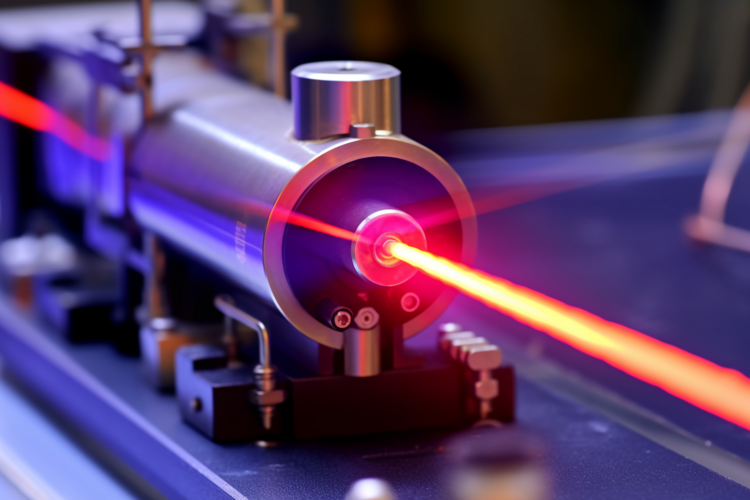

Precision CNC & Investment-Cast Components for Photonics and Laser Systems

In photonics, a few microns of error can scatter a beam, shift a wavelength, or cripple an entire optical path. Rollyu Precision delivers the ultra-tight-tolerance brackets, holders, housings, and heat-management parts that keep lasers on target and optical assemblies perfectly aligned—shift after shift, year after year.

Why Photonics & Laser OEMs Choose Rollyu

Your Challenge | Our Solution | Benefit |

Sub-micron alignment of lenses, mirrors, and diode stacks | 5-axis CNC milling & Swiss turning to ±0.005 mm | Repeatable optical performance across production runs |

Thermal stability in high-power lasers | Copper-inlay heat sinks, vacuum-brazed water-blocks | Lower junction temps, longer diode life |

Vibration isolation for sensitive interferometers | Stress-relieved Invar frames, honeycomb optical-table inserts | Stable beam paths, sharper metrology results |

Rapid design iterations | Quick-turn prototypes in aluminum, titanium, or specialty plastics | Faster R&D cycles, shorter time-to-market |

Core Components We Machine and Cast

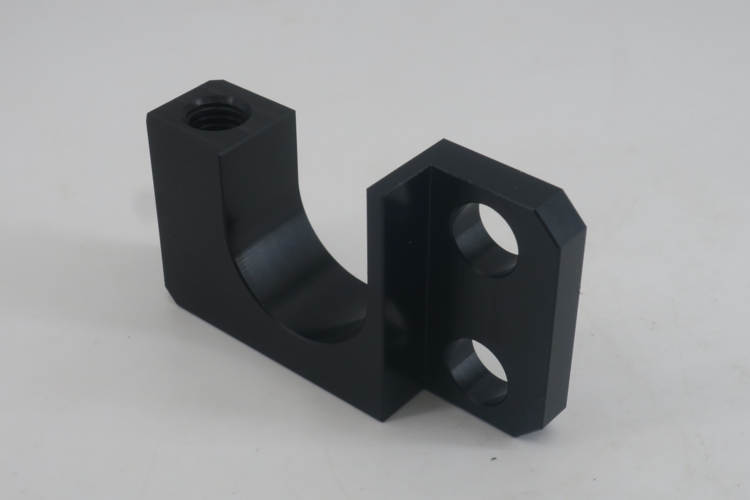

Opto-Mechanical Hardware

Lens & mirror mounts with fine-pitch adjustment screws

Kinematic bases for repeatable swap-in / swap-out alignment

Gimbal assemblies for galvo scanners and beam-steering modules

Precision rails & translation stages with low-friction coatings

Laser-System Parts

Diode-array cold plates featuring micro-milled coolant channels

Pump-cavity housings in electroless-nickel-plated aluminum

Optical isolator yokes machined from low-permeability stainless steel

Q-switch holders and Pockels-cell brackets with integrated cable routing

Photonics Accessories

Fiber-collimator sleeves and aspheric lens barrels

Beam-splitter cubes with dowel-pin datum faces for automated assembly

Custom apertures, diaphragms, and filter wheels balanced for high-RPM use

Materials Tailored to Optical Performance

6061-T6 & 7075-T6 Aluminum – Lightweight, good CTE match for glass.

Titanium 6Al-4V – High stiffness-to-mass; ideal for space-constrained laser heads.

Oxygen-Free Copper – Exceptional thermal conductivity for diode laser cold plates.

Invar & Super-Invar – Ultra-low CTE for precision metrology frames.

Black-anodized Aluminum & E-Ni – Stray-light suppression and corrosion resistance.

All materials are fully traceable and supplied with mill certs to meet ISO 13485 and AS9100 documentation requirements.

Manufacturing Toolbox

Ultra-Precision 5-Axis CNC Machining

Complex light-weighted geometries and compound angles machined in a single setup.

Investment Casting + Finish Machining

Near-net brackets and housings in aluminum or stainless, reducing waste and cost.

Wire EDM & Micro-Drilling (Ø0.1 mm)

Burr-free apertures and coolant orifices without secondary deburring.

Laser Welding & Helium Leak-Testing

Hermetic sealing for vacuum chambers and gas-laser enclosures.

In-Process Metrology

CMM with 0.8 µm touch probes and white-light interferometry ensure every critical surface meets spec.

Quality That Travels the Whole Beam Path

First Article Inspection (FAI)

100 % dimensional and cosmetic check on optical-critical faces

PPAP, FAIR, and full CoC supplied with every lot

From Lab Prototype to Series Production

Whether you need ten prototype mirror mounts for a new femtosecond laser or 20 000 beam-steering brackets for an industrial marking system, we scale effortlessly—without diluting quality.

Prototype lead time: as fast as 7 days

Production lead time: typical 3–5 weeks with Kanban and safety-stock options

Global logistics: air or sea, DDP incoterms on request

Light Starts Here—Let’s Build It Together

Ready to tighten your beam divergence, shrink thermal drift, or cut weeks off your build schedule? Send your 3D models or RFQ to our engineering team today.

info@rymachining.com

Rollyu Precision — Machining the parts that move light.