Home >> Industries

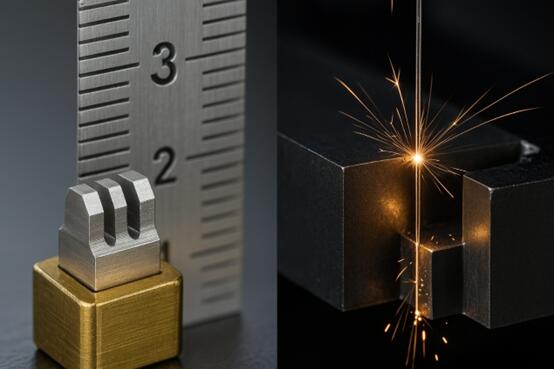

Micro-machining and Electrical Discharge Machining (EDM) are closely related, with micro-EDM being a specialized form of EDM used for creating micro-scale features and intricate shapes in difficult-to-machine materials. EDM uses electrical discharges to remove material through melting and vaporization, while micro-EDM adapts this process for smaller features and higher precision.

At Rollyu Precision, both micro-machining and EDM are advanced CNC technologies used when tight tolerances, fine features, and difficult materials are involved. They’re essential in industries like medical devices, aerospace, semiconductors, dental equipment, and watchmaking.

Micro-Machining: Precision at the Micron Scale

What It Is:

Micro-machining involves using extremely small tools (often <1 mm in diameter) to machine intricate geometries or tight features with ultra-high precision. It's used to manufacture microcomponents, micro-dies, micro-molds, and other micro-devices. Micro-machining techniques include mechanical methods like drilling and milling, as well as non-mechanical methods like EDM.

Key Features:

Tool sizes down to 0.1 mm or smaller

Tolerances as tight as ±1 µm

Compatible with metals and plastics

Typically performed using high-speed spindles and advanced CNC mills

Used For:

Micro-holes and channels

Medical implants and stents

Micro-electronics components

EDM (Electrical Discharge Machining): No-Contact Material Removal

What It Is:

EDM removes material using electrical discharges (sparks) between a tool electrode and the workpiece, ideal for very hard or fragile materials. The process involves a spark between an electrode and the workpiece, generating intense heat that melts and vaporizes the material. EDM is commonly used for hard-to-machine materials like hardened steels and alloys.

Key Types:

Wire EDM: Uses a thin wire to cut through the part (like a bandsaw)

Sinker EDM: Uses shaped electrodes to erode cavities

Advantages:

Can machine extremely hard materials (tool steels, titanium, Inconel)

Produces complex internal features and sharp corners

No mechanical stress during machining

Used For:

Mold cavities and dies

Aerospace turbine components

Medical surgical tools

What is Micro-EDM?

Micro-EDM is a specialized form of EDM tailored for micro-scale machining. It allows for the creation of very small holes, intricate shapes, and high-precision features. Micro-EDM is particularly useful for creating features on difficult-to-machine materials, such as those used in electronics, medical devices, and aerospace applications.

How Micro-EDM Works

Micro-EDM utilizes tiny electrical discharges to remove material.

The size of the plasma channel (the area where the spark occurs) is smaller in micro-EDM compared to traditional EDM.

This allows for the creation of finer details and higher precision.

Micro-machining and EDM Comparison Snapshot

Feature | Micro-Machining | EDM |

Material Contact | Yes (cutting tools) | No (electrical erosion) |

Best For | Tiny geometries, tight tolerances | Complex profiles in hard metals |

Speed | Fast for soft materials | Slower but highly precise |

Surface Finish | Good (with polishing) | Very good, low stress |

Tool Wear | High | Low (non-contact) |

In summary, Micro-machining and EDM are valuable tools for micro-machining, offering high precision, the ability to machine difficult materials, and the creation of complex shapes. It plays a crucial role in various industries, from medical devices to electronics, and continues to advance with new technologies and applications.

Previous: None