Home >> Industries

At Rollyu Precision, we provide high-accuracy CNC machining, die casting, rapid prototyping and sheet metal fabrication services for advanced industries that demand uncompromising quality and consistency. Our ISO 9001 and ISO 13485-certified capabilities support both rapid prototyping and volume production of tight-tolerance components. We work with leading companies across medical devices, dental equipment, life sciences, robotics, semiconductor manufacturing, industrial automation, renewable energy, and aerospace sectors. Whether you're developing surgical instruments, semiconductor tooling, lab automation systems, or lightweight satellite structures, Rollyu delivers precision-machined parts with full traceability, material control, and process reliability — every time.

Excellence in Surgical Device Manufacturing

Surgical procedures demand the highest quality components—there is zero room for compromise. Rollyu Precision delivers micro-scale surgical tools and implant components machined from materials like titanium and stainless steel, using 5-axis CNC machining and EDM technologies.

Our facility produces precision parts for:

LASIK equipment

Cardiac devices and miniature gears

Orthopedic titanium implants

Implantable medical devices

Custom surgical instruments

Each component is crafted under tightly controlled conditions to ensure sterility, dimensional accuracy, and flawless function in the operating room.

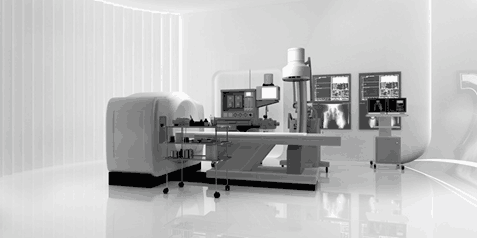

Laboratory and Diagnostic Equipment Manufacturing

Our clients in the diagnostic and life sciences sectors rely on us to deliver high-performance components used in laboratory automation and DNA analysis. We manufacture insertion tools, sample handling fixtures, and structural supports used in sensitive testing environments where accuracy is critical.

Parts like MRI table components, collimators for CT scanners, and X-ray anodes are engineered to operate reliably even in mobile or high-radiation environments.

Radiology-Grade Micromachining & EDM Services

Radiologists and imaging engineers depend on precision-machined parts that function in real-time during procedures. Our EDM machining services are ideal for complex geometries, heat-sensitive alloys, and miniature components used in:

MRI systems

CT scanners

X-ray and fluoroscopy machines

We ensure dimensional integrity, electrical conductivity where needed, and component reliability under repeated use.

Why Medical Clients Choose Rollyu Precision

Speed: Rapid prototyping, bridge tooling, and low-volume production with turnaround times as fast as 1–3 days.

Accuracy: Sub-millimeter and micron-level tolerances on complex geometries.

Materials: Experience with high-temperature plastics (PEEK, PEI), titanium, stainless steel, Inconel, and medical-grade aluminum.

Certifications: ISO 9001:2015 certified facility with full traceability and documentation.

Customization: DFM support, surface finishing (anodizing, passivation, plating), and packaging options tailored to medical environments.

Materials We Machine for Medical Applications

Rollyu’s expertise spans a wide range of materials suitable for critical medical applications:

Titanium & Inconel: Lightweight, corrosion-resistant, ideal for orthopedic and implantable components.

Stainless Steel: Durable and sterilization-ready for surgical tools and lab equipment.

Aluminum: Lightweight and cost-effective, often used in housings and structural supports.

PEEK & PEI (Ultem): High-performance thermoplastics for components exposed to heat, pressure, and chemical sterilization.

Applications We Serve

From concept to production, we support medical engineers, R&D teams, and OEMs across a variety of applications:

Surgical instruments

Handheld diagnostic tools

Ventilators and respiratory systems

Wearables and prosthetics

Implantable prototypes

Cartridge and housing systems

Dental Equipment

We Machine the Impossible

Many shops hesitate to take on complex or unconventional designs. At Rollyu Precision, those are the projects we specialize in. Whether you’re designing the next breakthrough in minimally invasive surgery or need ultra-precise components for a wearable health device, we’re here to make it real.

Our experienced engineers thrive on solving difficult challenges, iterating prototypes, and achieving what others consider impossible. We don’t just deliver parts—we deliver possibilities.

Partner with Rollyu Precision

We invite you to collaborate with our team for your next medical machining project. With speed, precision, and uncompromising quality, Rollyu helps accelerate your innovation from idea to reality.

Looking for a manufacturing partner that understands medical risk, regulatory requirements, and precision engineering?

Work with Rollyu Precision to turn complex designs into production-ready medical components — with speed, accuracy, and full traceability.

Previous: None

Next: Applications by Industry