Home >> Industries

Precision Machining for Motion Control & Instrumentation

Guide to Building Faster, Smarter, and More Reliable Systems—with Components You Can Trust

Keeping a robot arm on its path, a wafer stage perfectly aligned, or a flight-critical sensor rock-steady under 9 g’s all boils down to one unglamorous reality: the mechanical chain must be as precise, durable, and repeatable as the software commanding it. Every plate, block, bracket, or shaft is a literal link in that chain. If the link flexes, wears, or drifts, your entire motion-control loop degrades—sometimes catastrophically.

At Rollyu Precision, we machine those links to aerospace-grade tolerances, day in and day out. This deep-dive article explains why custom precision machining sits at the heart of modern motion control and instrumentation, how the right materials and processes influence performance, and why partnering with a specialist like Rollyu accelerates your time-to-market while safeguarding long-term reliability.

1 | Why Motion-Control OEMs Talk Microns, Not Millimeters

Motion control is fundamentally about closed-loop accuracy—the system’s ability to reach a commanded position, speed, or force and stay there without oscillation or drift. Two numbers summarize the challenge:

Repeatability: the range within which the system returns to a setpoint after multiple moves

Resolution: the smallest incremental change the system can detect or produce

Error sources—backlash, thermal growth, vibration, bearing friction—are overwhelmingly mechanical. That means the success of your PID or model-predictive algorithm depends on physical components that:

Hold geometry within single-digit micron tolerances

Maintain those tolerances after millions of cycles

Resist corrosion, wear, and contamination in harsh environments

Integrate seamlessly with sensors, encoders, and actuators

Precision machining is how we achieve those goals at production volume.

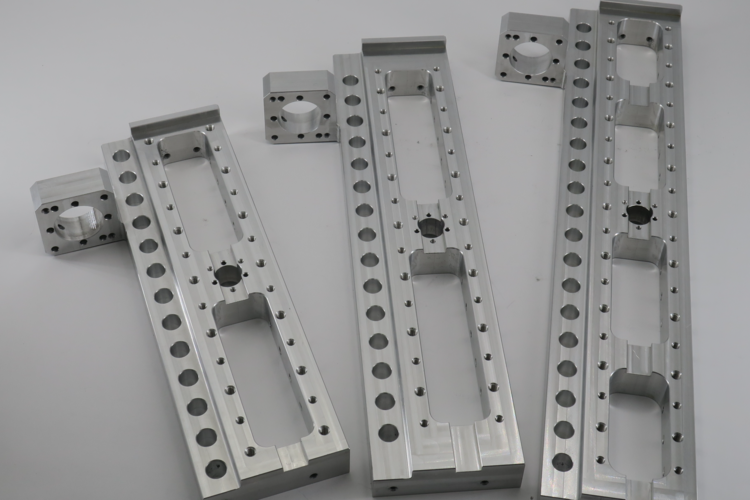

2 | Key Precision-Machined Components in Motion-Control Systems

2.1 Gears & Gearboxes

Helical, spur, planetary, harmonic, cycloidal—each gear topology has pros and cons for torque density, backlash, and efficiency. What they share is a need for profile accuracy (DIN 5 or better) and surface finishes that permit an oil film as thin as 0.5 µm. Rollyu cuts gears on 5-axis machining centers, finishes them with grinding or honing, and checks every tooth flank on CNC gear analyzers.

2.2 Shafts, Bearings, and Couplings

A shaft out-of-round by just 3 µm produces uneven preload on precision angular-contact bearings, shortening their L10 life. We machine shafts to ≤2 µm roundness, hard-turn journals after heat-treat, and measure them on air-gauging stations. Couplings—Oldham, bellows, or zero-backlash jaw—are machined from aluminum, stainless, or titanium depending on inertia targets.

2.3 Actuators

Ball-screw nuts, voice-coil armatures, hydraulic pistons, pneumatic slides. All depend on precise lead accuracy and low-friction mating surfaces. Rollyu single-point threads ball-screw nuts to ISO class 4, then matches them to screws after laser-interferometer mapping.

2.4 Cams & Followers

Packaging machines and pick-and-place heads rely on cam profiles that convert rotary to complex linear motion. We EDM hard-steel cams to ±5 µm profile deviation and finish with isotropic super-finishing to extend follower life.

2.5 Linear Guides & Ball Screws

Guide rails must be flat within 2 µm over 1 m to avoid binding. Ball-screw shafts demand lead error under 8 µm/300 mm for semiconductor steppers. Rollyu machines rails from through-hardened tool steel, then lap reference faces for straightness and squareness.

3 | Instrumentation: Housing the Brains, Protecting the Senses

3.1 Sensor Mounts

An IMU measuring aircraft attitude drifts if its housing warps 5 µm with temperature. We machine housings from 6061-T6 or Invar, using orbital end-milling that minimizes burrs and preserves flatness.

3.2 Valves & Flow Controllers

In gas chromatographs or laser cooling loops, flow must vary less than 0.2 %. Needle valves we machine from 316 SS feature seat concentricity under 3 µm; matched cones and seats are lapped in pairs.

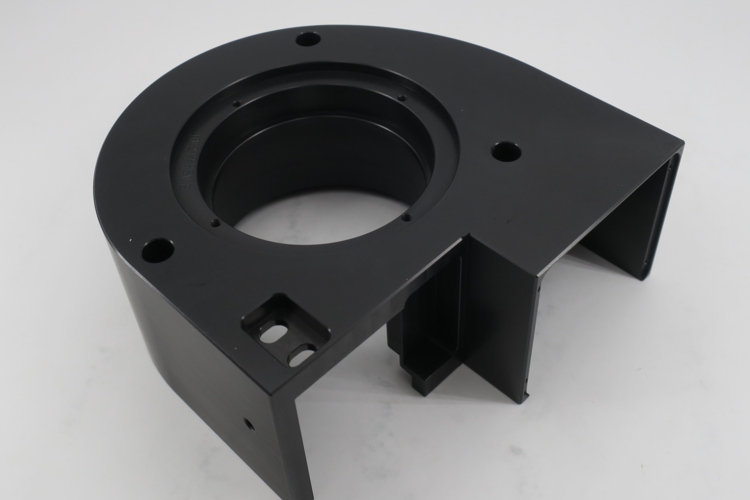

3.3 Optics Mounts

A 10 µrad tilt in a mirror mount derails interferometer accuracy. Rollyu mills gimbal rings, taps flexure hinges, and anodizes to suppress stray light—then verifies angular repeatability on autocollimation benches.

3.4 Precision Fasteners, Inserts & Pins

Thread class, concentricity, and tensile strength matter when sub-assemblies must be field-serviceable yet rock-solid. We roll threads rather than cut them for superior fatigue resistance, and we press stainless inserts into polymer housings for unified CTE behavior.

4 | Material Selection: The Unsung Hero of Accuracy

Material | Why We Use It in Motion Control |

17-4 PH Stainless | High strength & good machinability; age-hardens without distortion |

7075-T6 Aluminum | 60 % the weight of steel, double the yield strength of 6061 |

PEEK/PEI | Chemically inert, low outgassing; perfect for semiconductor tools |

Invar | CTE ≈ 1.2 µm/m-°C, essential for optical benches and cryostats |

Brass/Copper | Excellent electrical & thermal conductivity; ideal for high-frequency connectors |

Every batch arrives with full mill certs; we verify composition via handheld XRF and track heat numbers through our ERP.

5 | Manufacturing Toolbox: From Rough Stock to Nanometer-Grade Parts

Ultra-Precision CNC (5-Axis, Mill-Turn)

Positional accuracy ±3 µm

Renishaw OTS & RTS probes for in-cycle datum verification

Wire-EDM & Sinker-EDM

Cut 64 HRC tool steel with 0.005 mm corner radii

Gun-Drilling & Deep-Hole BTA

Coolant passages Ø0.5 mm × 200 mm without drift

Laser & Waterjet

Prototype brackets in hours, not days, while preserving temper

Surface Engineering

Nitriding for >1,200 HV, electroless nickel for 1,000-hour salt-spray, black-oxide for glare reduction

Lights-Out Automation

Pallet pools and robotic tending keep spindles cutting 24 / 7; SPC data is logged to our MES in real time.

6 | Quality Assurance & Traceability

CMM & Vision Inspection – 0.7 µm volumetric accuracy

Roundness & Surface Finish – Talyrond and white-light interferometry down to 3 nm Ra

Environmental Stress Screening – thermal cycling from −40 °C to +120 °C for aerospace parts

Clean-Room Packaging (ISO Class 7) – essential for optics and life-science assemblies

Results are posted to a secure portal; customers download FAIRs, PPAP packs, and Certificates of Conformance 24 / 7.

7 | Applications & Case Snapshots

7.1 Robotics—High-Speed Delta Pickers

A food-packaging OEM cut cycle time 12 % after switching to Rollyu-machined carbon-fiber flange plates with titanium inserts, shaving 750 g off end-effector mass.

7.2 Aerospace—Gimbal Stabilizers for EO/IR Pods

We delivered Invar yaw brackets with ±5 µm flatness; after 1,000-hour HALT vibration, angular drift was <0.02°. The pod passed DO-160G thermal and shock on first try.

7.3 Semiconductor—300 mm Wafer Handlers

Integrators replaced ground stainless shafts with Rollyu’s ceramic-coated aluminum shafts, reducing particle generation to ISO Class 1 compliance.

7.4 Medical—Robotic Surgery Tools

We machined 1.5 mm-diameter drive rods of 465 SS; diamantine polish yielded Ra = 0.02 µm, minimizing tissue drag and surgeon hand-tremor amplification.

8 | Design-for-Manufacturability Support

Early involvement saves weeks later. Our application engineers review CAD for tolerancing stack-ups, suggest cost-effective datum schemes, and flag surfaces where grinding or honing can be eliminated. Typical feedback turnaround: 48 hours. Prototypes ship in 5–7 working days, allowing your dev team to validate concepts sooner and iterate faster.

9 | Sustainability & Continuous Improvement

Chip Recycling: 98 % of aluminum and steel chips are segregated and returned to the smelter.

Cutting-Fluid Filtration: Microfiltration reduces tramp oil by 90 %, extending tool life and minimizing waste.

Energy Dashboard: Live monitoring of spindle load vs. power draw identifies efficiency gains; we reduced kWh per machined kilogram by 22 % in two years.

Every improvement feeds our ISO 14001 environmental objectives—your green-supply-chain reporting has never been easier.

10 | Why Rollyu?

Certifications: ISO 9001, ISO 13485, AS9100 (in progress)

Global Logistics: Consolidated air-freight, DDP terms, Kanban stocking in the U.S. and EU

Customer Retention: 97 % five-year average—because we solve problems, not just ship parts

Scalability: Prototype quantities of 5 pcs scale to 50,000 pcs/yr with SPC controls intact

Ready to Move Faster, More Precisely, and More Reliably?

Your next breakthrough in motion control or instrumentation deserves components that perform beyond spec—from day one to end-of-life. Email your drawings or RFQ to our engineering desk today and experience why engineers in robotics, aerospace, semiconductor, and life-science markets call Rollyu their machine shop.

info@rymachining.com

Rollyu Precision – Because Microns Matter, and So Does Your Deadline.

Previous: Precision Machining Parts for Hydraulic

Next: None