Jan. 14, 2026

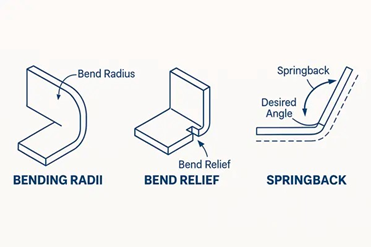

Bending radii, bend relief, springback

Bending Radii, Bend Relief & Springback — Key Factors in Precision CNC Bending

At Rollyu Precision, achieving tight-tolerance, high-quality bends requires more than simply programming angles — it requires full control of bending radii, bend relief, and springback compensation. These factors directly affect dimensional accuracy, part fit, structural integrity, and long-term performance, particularly for industries like medical devices, photonics, semiconductors, and industrial automation.

1️ Bending Radii (Inside Bend Radius)

The inside bend radius is the radius measured at the interior of the bend. It is one of the most critical design parameters in sheet metal bending because it directly affects:

Part strength

Dimensional stability

Appearance (especially for cosmetic parts)

Risk of cracking (particularly in harder or thinner materials)

✅ General Best Practices:

Material Type | Minimum Recommended Inside Bend Radius |

Aluminum (5052, 6061) | 1.0 × material thickness |

Stainless Steel (304, 316) | 1.5 × material thickness |

Mild Steel (SPCC, A36) | 1.0 × material thickness |

Titanium & Specialty Alloys | 1.5–2.0 × material thickness |

Designing with proper bend radii minimizes material stress, prevents cracking, and allows for consistent repeatable bends in production.

2Bend Relief

Bend relief is a small notch or cutout placed at the ends of a bend to:

Prevent tearing or distortion at the bend corner

Eliminate material bulging in tight areas

Improve dimensional control during bending

Allow adjacent flanges to form correctly without interference

✅ Design Guidelines:

Relief width: ≥ material thickness

Relief length: slightly longer than bend radius + material thickness

Bend relief becomes particularly important for tight corner bends, enclosed flanges, or when multiple bends are located close together.

3️ Springback Compensation

Springback occurs because metal naturally tries to return to its original flat shape after bending. The amount of springback depends on:

Material type (harder materials have more springback)

Thickness

Bend angle

Bend radius

✅ How Rollyu Precision Controls Springback:

CNC Programming: Automatic compensation calculated into the programmed bend angle.

Test Bends: Sample bends to verify exact springback for each material lot.

Material Lot Traceability: Consistent material sourcing ensures predictable springback behavior.

Tooling Adjustments: Precision tooling allows fine-tuning of punch/die combinations to control bend radius and angle.

✅ Typical Springback by Material:

Material Type | Springback Range |

Aluminum (5052) | ~0.5° – 2.0° |

Stainless Steel (304, 316) | ~1.5° – 4.0° |

Mild Steel (SPCC) | ~1.0° – 3.0° |

Why These Details Matter

For medical devices, incorrect bend radii or uncontrolled springback can prevent proper assembly and cause field failures.

For semiconductor equipment, even slight dimensional deviations may lead to improper fit within cleanroom tools.

For photonics and automation frames, perfect corner alignment ensures optical stability and machine repeatability.

Rollyu Precision — Expert Control of Every Bend

By carefully managing bending radii, reliefs, and springback, Rollyu Precision consistently delivers CNC bent parts that meet exacting functional, cosmetic, and regulatory requirements. Our CNC press brakes, precision tooling, and experienced engineers ensure dimensional stability even in complex multi-bend designs.

If your sheet metal designs involve tight bend radii, dense bend patterns, or high assembly sensitivity, early engineering alignment makes a measurable difference.

For technical discussion, DFM review, or CNC bending support:

Previous: None

Next: Fabrication Processes at Rollyu · Tolerances & edge quality