Jan. 15, 2026

Welding Processes at Rollyu Precision: TIG, MIG & Spot Welding

At Rollyu Precision, welding plays a critical role in our sheet metal fabrication, CNC assemblies, and structural frame production. Depending on material type, part geometry, thickness, and application requirements, we apply the most suitable welding process to ensure structural integrity, cosmetic quality, and manufacturing efficiency.

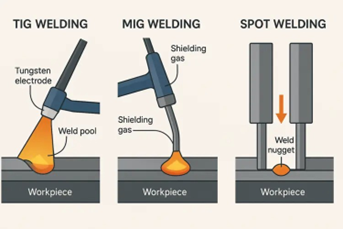

TIG Welding (Gas Tungsten Arc Welding, GTAW) delivers exceptionally clean, high-quality welds using a non-consumable tungsten electrode and inert shielding gas. This method excels in joining thin materials, stainless steels, and precision components where appearance, minimal distortion, and superior weld integrity are critical.

MIG Welding (Gas Metal Arc Welding, GMAW) offers high deposition rates and excellent productivity by feeding a consumable wire electrode through the welding gun while shielding gas protects the weld zone. MIG welding is ideal for thicker materials, larger assemblies, and high-throughput production where speed and versatility are important.

Spot Welding (Resistance Welding) is widely used for joining overlapping sheet metal sections, especially in high-volume production of thin-gauge parts. Heat generated by electrical resistance quickly fuses the metal surfaces, producing consistent and repeatable welds with minimal cycle times and low material distortion.

At Rollyu Precision, our certified welders, controlled processes, and in-house fixturing capabilities ensure each weld meets demanding specifications for strength, consistency, and cosmetic finish—whether for medical devices, automation systems, semiconductor equipment, or aerospace assemblies.

1️TIG Welding (Gas Tungsten Arc Welding – GTAW)

Overview:

TIG welding uses a non-consumable tungsten electrode and an inert gas (typically Argon) to shield the weld area fro m atmospheric contamination. It produces precise, clean welds with minimal spatter — ideal for thin-gauge metals and parts requiring high cosmetic appearance.

Applications:

Stainless steel enclosures

Aluminum frames and brackets

Medical device housings

Semiconductor chamber assemblies

Aerospace structural components

Advantages:

High precision, excellent control

Clean welds with low contamination

Suitable for thin and thick materials

Excellent for dissimilar metals (with proper technique)

Limitations:

Slower than other welding processes

Requires highly skilled welders

Less cost-effective for high-volume production

2️ MIG Welding (Gas Metal Arc Welding – GMAW)

Overview:

MIG welding uses a continuously fed consumable wire electrode and shielding gas. It is faster and more efficient for thicker materials or high-volume production.

Applications:

Structural frames

Automation equipment components

Industrial enclosures

Agricultural and heavy equipment parts

Advantages:

Faster welding speed

Easier to automate for production runs

Lower operator skill threshold

Good for thicker gauge metals

Limitations:

More spatter than TIG

Less precise for thin materials

May require more post-weld cleanup

3️ Spot Welding (Resistance Spot Welding)

Overview:

Spot welding is widely used for joining overlapping sheet metal pieces, particularly in high-volume production of thin gauge metal parts. It relies on pressure and electric current to create localized heat that forms the weld nugget.

Applications:

Sheet metal enclosures

Automotive panels

Electrical cabinets

HVAC and appliance components

Advantages:

Extremely fast cycle times

Low material distortion

No filler material required

Consistent, repeatable weld quality for thin sheets

Limitations:

Primarily limited to thin sheet metals

Less effective for complex geometries

Requires good surface preparation and fit-up