Jan. 16, 2026

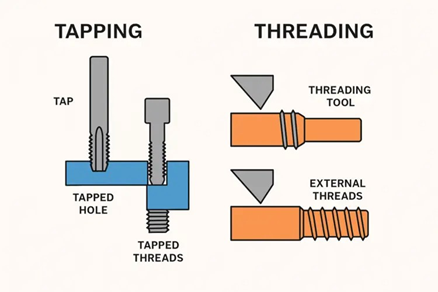

Tapping and Threading in Sheet Metal Fabrication

In sheet metal fabrication, creating internal threads allows for secure assembly of enclosures, brackets, panels, and structural frames. Depending on material type, thickness, and application, two primary methods are used:

1️ Cut Tapping (Conventional Tapping)

A cutting tap is used to remove material and create internal threads, suitable for most metals.

Suitable for most metals, including aluminum, carbon steel, stainless steel, titanium, and copper alloys.

Delivers precise threads for thin and thick materials alike.

Commonly used for precision enclosures, mounting plates, and robotic frames where assembly strength and repeatability are critical.

2️ Thread Forming (Roll Tapping)

Cold-forms threads without removing material; improves strength in ductile materials like aluminum, brass, and soft steels.Cold-forms the threads by displacing material without cutting.

Ideal for ductile materials like aluminum alloys, soft steels, brass, and copper.

Produces stronger threads due to work-hardening and uninterrupted grain structure.

Reduces the risk of chip contamination, making it well-suited for medical, semiconductor, and cleanroom environments where loose chips are unacceptable.

Excellent for thin-wall sheet metal parts where thread strength must be maximized in limited material thickness.

Suitable Materials for Tapping & Threading

Material | Cut Tapping | Form Tapping | Thread Milling |

Aluminum Alloys | ✅ Excellent | ✅ Excellent | ✅ Excellent |

Stainless Steels | ✅ Excellent | ⚠ Limited (only ductile grades) | ✅ Excellent |

Carbon Steels | ✅ Excellent | ✅ Excellent | ✅ Excellent |

Titanium Alloys | ✅ Good (special taps) | ❌ Not Recommended | ✅ Preferred |

Copper Alloys | ✅ Excellent | ✅ Excellent | ✅ Excellent |

Plastics (Delrin, PEEK, Ultem) | ✅ Excellent | ✅ Excellent | ✅ Excellent |

Threading Standards & Capabilities

Metric Threads (M1.0 – M50)

Unified Threads (UNC, UNF, UNEF)

NPT, BSP, and custom pipe threads

Helicoil (thread insert) preparation and installation

Thread tolerances per ISO, ANSI, ASME, and DIN standards

Machine screw sizes down to #0-80

Quality Control for Threads

Go/No-Go thread plug gauges

Thread ring gauges for external threads

Visual inspection under magnification

Class 2B / 3B / 2A / 3A tolerances for critical threads

Material-specific process controls to avoid galling or thread tearing

Why Tapping & Threading Matter

Precision threads are essential for:

Surgical device assemblies

Semiconductor fixture components

Automation brackets and adjustment mechanisms

Aerospace sensor mounts

Medical robotics housings

Improper thread quality can lead to fastener failure, torque inconsistencies, misalignment, or long-term fatigue issues — especially in industries where every component must meet strict reliability, cleanliness, and assembly repeatability requirements.

Rollyu Precision Advantages

Multi-process CNC threading integration (turning, milling, tapping)

In-house tool management for micro-threads and special pitches

Full documentation & traceability under ISO 9001 & ISO 13485

Specialized tapping for medical-grade aluminum, stainless, titanium

High repeatability for both prototype and production runs

Thread quality directly affects assembly strength, torque consistency, and long-term reliability—especially in thin-wall sheet metal parts.

If you have questions about tapping method selection, thread strength, or material suitability for your application, our engineering team is ready to support you.