Jan. 11, 2026

Photonics CNC Machining

Stability-Driven Manufacturing for Optical Systems That Must Hold Alignment

In photonics systems, passing inspection is not enough.

Many optical assemblies drift not because CNC parts are out of tolerance,

but because system behavior was never engineered at the manufacturing stage.

At Rollyu Precision, we machine photonics hardware that stays stable after assembly, thermal cycling, and time—not just parts that look good on a CMM report.

Why Photonics Machining Is Different

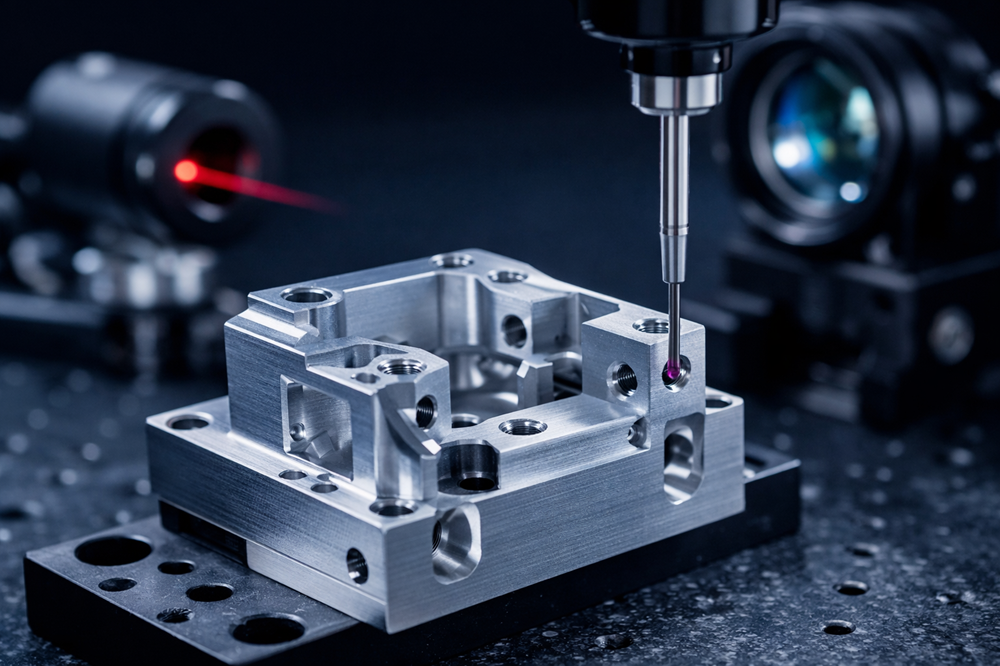

Photonics machining is not conventional precision machining.

Optical performance depends on:

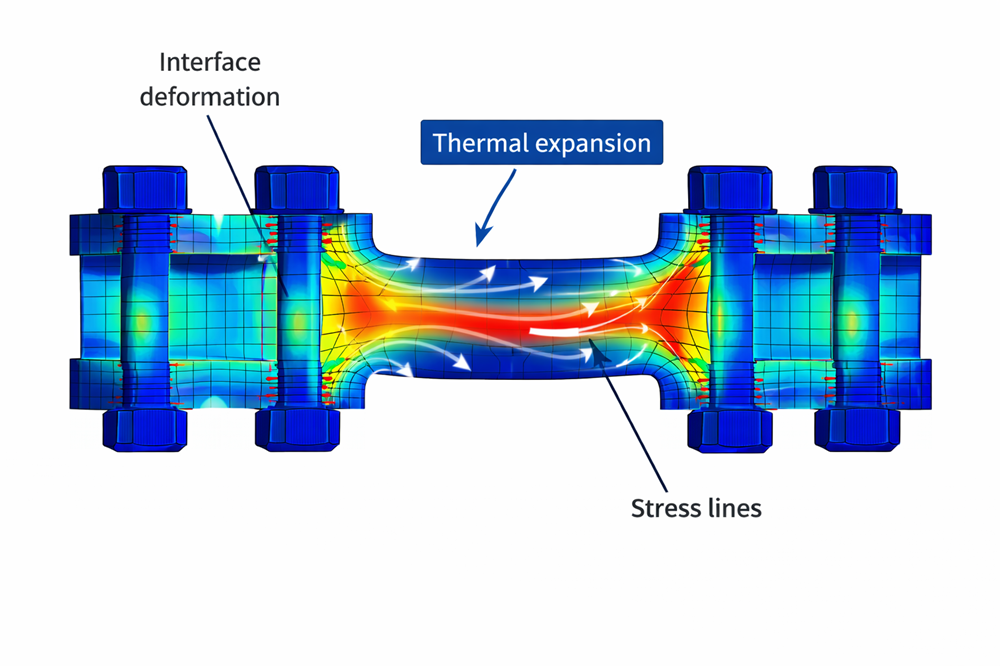

Interface behavior

Assembly preload

Residual stress

Thermal-mechanical interaction

These factors are invisible to dimensional inspection, yet they determine whether a system holds alignment or drifts in the field.

That is why CNC machining for photonics must be approached as a system-stability problem, not a tolerance-only exercise.

What We Actually Engineer (Beyond Tolerances)

1. Interface Stability, Not Just Geometry

We pay close attention to:

Mating surfaces

Contact stiffness

Surface finish at load-bearing interfaces

Because in photonics assemblies, interfaces—not features—control alignment over time.

2. Stress-Controlled Machining

Residual stress is one of the most common causes of post-inspection drift.

Our process includes:

Multi-stage roughing and finishing

Stress relief between machining stages

Low-pressure finishing passes

The goal is simple:

the geometry you measure is the geometry you keep.

3. Assembly-Aware Manufacturing

Many CNC parts pass inspection but deform once clamped or fastened.

We account for:

Clamping distortion during machining

Assembly preload paths

Real mounting conditions

For critical parts, we apply free-state or simulated-state machining to avoid elastic spring-back after assembly.

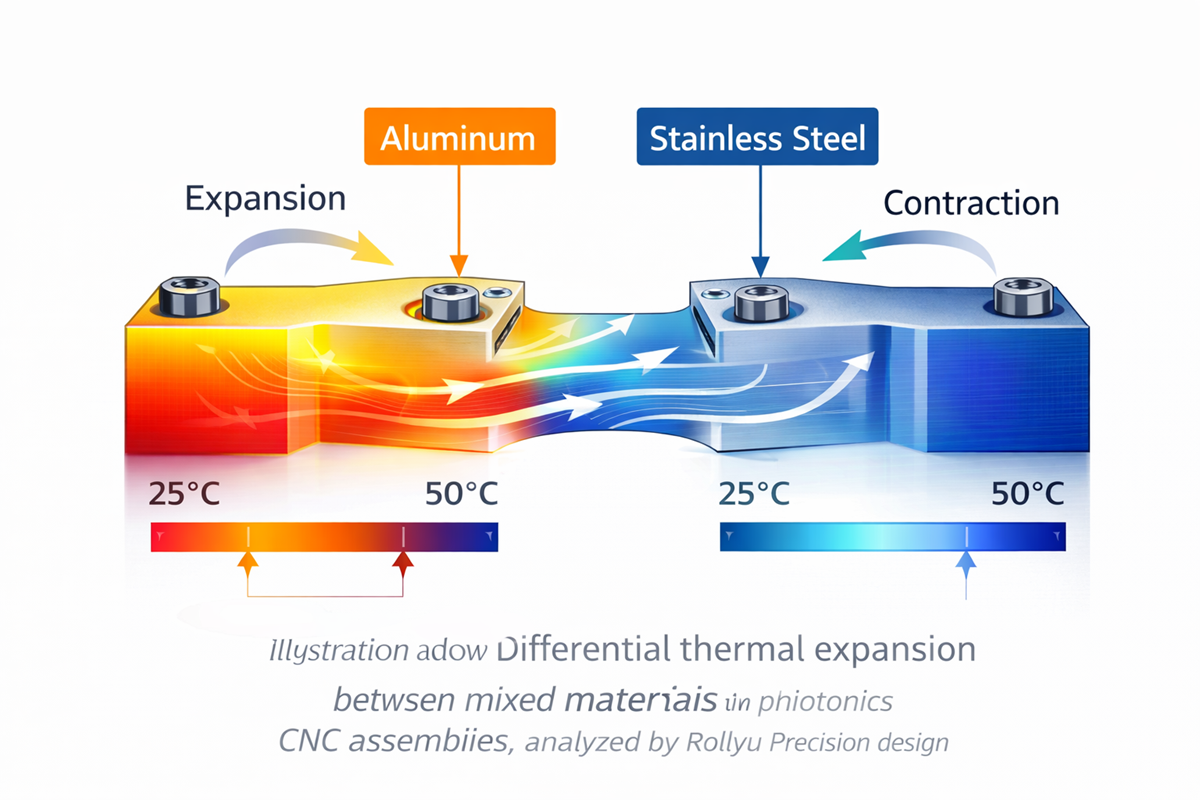

4. Thermal Behavior Consideration

Photonics systems rarely operate at inspection conditions.

We help customers evaluate:

Material selection for thermal stability

Mixed-material assemblies

Thermal cycling risk

Because thermal hysteresis can undo perfect alignment.

Typical Photonics Components We Machine

Optical benches and baseplates

Laser housings and enclosures

Kinematic mounts and brackets

Alignment frames and sub-assemblies

Custom opto-mechanical structures

Materials commonly include:

Aluminum 6061 / 7075

Stainless steel 304 / 316

Titanium alloys (on request)

Quality Control: What We Measure—and What We Question

We use CMM inspection to verify geometry, flatness, and positional accuracy.

But we do not stop there.

We actively question:

Where stress is stored after assembly

Which interfaces control alignment

What changes after thermal cycling

Because CMM reports confirm dimensions—not system stability.

When Customers Typically Contact Us

Customers usually reach out when:

Optical alignment drifts after assembly

Prototypes pass inspection but fail at scale

Systems lose stability after shipping or thermal cycling

Multiple suppliers “meet spec” but performance varies

In most cases, the issue is not tolerance—it is manufacturing behavior.

Our Role in Your Photonics Project

We are not just a machining vendor.

We act as a manufacturing partner who helps:

Identify stability risks early

Challenge assumptions before design freeze

Reduce late-stage surprises

Especially for photonics hardware where mistakes are expensive and often irreversible.

Let’s Talk About Stability—Before It Becomes a Problem

If your photonics system requires:

Long-term alignment stability

Predictable behavior after assembly

Manufacturing that supports optical performance

We are happy to review your design or discuss your application.