Jan. 31, 2026

Quality Assurance in Sheet Metal Operations

In precision sheet metal fabrication, quality assurance is not simply a final step; it’s a fully integrated system embedded throughout the entire production process. Effective quality control ensures that every fabricated part consistently meets its dimensional, cosmetic, and functional requirements — protecting both product performance and customer confidence.

Quality control and inspection in sheet metal fabrication are essential for:

Preventing dimensional non-conformances and assembly issues

Ensuring each part complies with customer drawings and specifications

Supporting ISO 9001 and ISO 13485 regulatory compliance

Protecting cosmetic surfaces for customer-facing components

Reducing costly scrap, rework, or downstream failure

Enabling long-term consistency in high-volume manufacturing

At Rollyu Precision, quality assurance is not treated as a final checkpoint. Instead, inspection and verification protocols are applied at every stage of fabrication — from material receipt to final packaging — ensuring each part satisfies both engineering tolerances and industry standards.

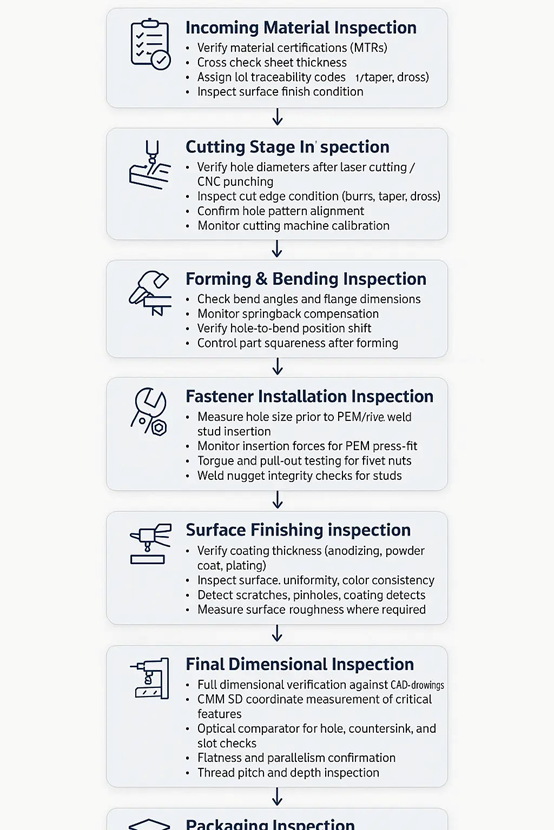

Multi-Stage Quality Control in Sheet Metal Fabrication

1️ Material Qualification

Verify material certifications (MTRs) and lot traceability

Confirm sheet thickness, alloy specifications, and surface condition

2️ Laser Cutting & CNC Punching Inspection

Measure hole diameters, patterns, and edge quality

Check cut-edge integrity to avoid downstream forming issues

Confirm machine alignment for consistent feature positioning

3️ Forming & Bending Inspection

Verify bend angles, flange lengths, and springback correction

Check hole-to-bend distances after forming

Control flatness, parallelism, and squareness post-bending

4️ Welding & Assembly Inspection

Visually inspect weld penetration, bead uniformity, and Heat-Affected Zone (HAZ)

Perform weld strength pull-testing when required

Monitor for weld distortion or warpage

5️ Fastener Installation Verification

Confirm hole sizing prior to PEM, rivet nut, or weld stud installation

Monitor insertion force and seating accuracy

Conduct torque and pull-out testing for fasteners

Inspect weld nugget integrity for projection welded studs

6️ Surface Finishing Inspection

Verify anodizing, powder coating, plating, or bead blasting coverage

Check surface uniformity, color consistency, and defect-free finish

Measure coating thickness and surface roughness where applicable

7️ Dimensional Inspection (Final QC)

Use CMM (Coordinate Measuring Machine) for full 3D verification

Apply optical comparator for non-contact hole and countersink measurement

Confirm flatness, parallelism, and warpage limits

Inspect threads for depth, pitch, and class tolerance compliance

8️ Packaging & Final Inspection

Perform cosmetic inspection before packaging

Verify part counts, labeling, and protective packaging application

Prepare inspection reports and traceability documentation for customer release

QC Tools Used at Rollyu Precision

Inspection Tool | Purpose |

CMM | Full dimensional accuracy verification |

Optical Comparator | Hole diameter & countersink angle measurement |

Torque Testers | Fastener strength validation |

Surface Roughness Testers | Finish quality control |

Coating Thickness Gauges | Anodize & plating verification |

Pull Testers | Fastener pull-out strength checks |

Industries Served with High QC Demands

Industry | QC Focus |

Medical Devices | Surface finish, dimensional repeatability, traceability |

Semiconductor Equipment | Vacuum-sealing surfaces, tight hole locations |

Photonics Assemblies | Alignment plate tolerances, cosmetic finishes |

Aerospace Structures | Lightweight assemblies, weld integrity, panel flatness |

Automation Systems | Assembly fit-up, hole repeatability, fastener strength |

The Result: Process-Driven Consistency

At Rollyu Precision, quality assurance is deeply integrated into every fabrication step to ensure dimensional repeatability, cosmetic perfection, and functional performance — even for industries where zero-defect manufacturing is mandatory.

By embedding inspection into every operation — not simply final QC — we help our customers achieve stable, compliant, and repeatable production outcomes that reduce risk, improve yield, and protect product reputation.

Have questions about inspection capability, tolerance control, or quality documentation for your sheet metal parts?

Contact our engineering team to discuss your quality requirements and inspection needs: