Mar. 03, 2023

What is the difference between 3-axis, 4-axis, and 5-axis machining?

In CNC machining, what is the difference between 3-axis, 4-axis, and 5-axis machining? What are the advantages of each? Which application are they suitable for?

CNC machining involves the use of computer numerical control (CNC) machines to shape and resize a piece of material (i.e. a workpiece) by automatically removing it. Typically, the material is plastic or metal, and when the removal is complete, the finished machining parts are already produced.

This process is also known as subtractive manufacturing. In order to perform CNC machining, computer applications are used to control the movement of the machine tool.

Common types of CNC machine tools:

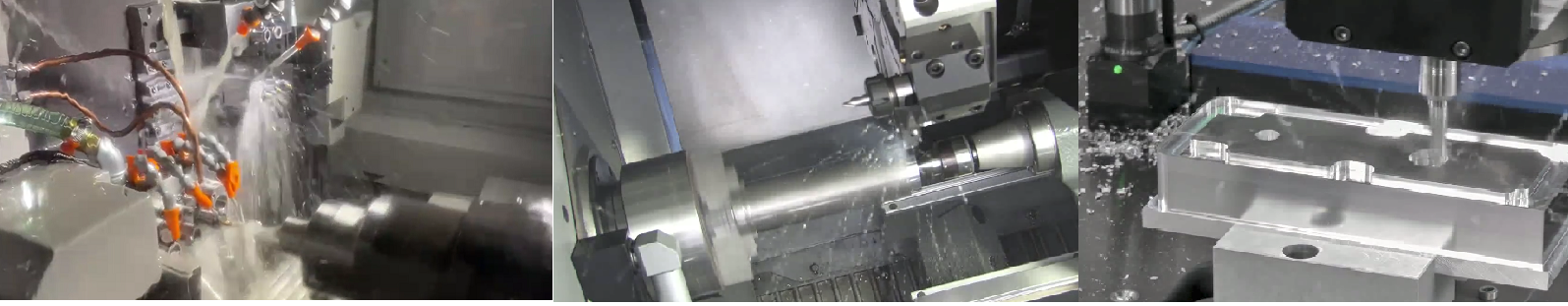

CNC machining processes include milling and turning, grinding, and EDM, etc.

Milling

Milling is the use of rotating tools on the surface of the workpiece, moving along 3, 4, or 5 axes. Milling is basically the cutting or finishing of a workpiece to quickly machine complex geometries and precision parts from metal or plastic.

Turning

Turning is the use of lathes to manufacture parts that contain cylindrical features. The workpiece rotates on the shaft and comes into contact with the precision turning tool to form circular edges, radial and axial holes, grooves.

Advantages of CNC machining

Compared to traditional manual machining, CNC machining is much faster. As long as the computer code is correct and in line with the design, the dimensional accuracy of the processed product is very high and the error is small.

Numerical control fabrication is the ideal rapid prototyping manufacturing method. It can also be used to manufacture end-use products and components; normally it is cost-effective in low-volume short-term production runs.

Multi-axis CNC machining

CNC milling involves removing material using rotary tools. Either the workpiece remains stationary and the tool moves to the workpiece, or the workpiece enters the machine at a predetermined angle. The more axes of motion a machine has, the more complex and faster the forming process.

3-axis CNC machining

Three-axis CNC milling is still one of the most popular and widely used machining techniques. In 3-axis machining, the workpiece remains fixed and the rotating tool cuts along the X, Y, and Z axes. This is a relatively simple form of CNC machining that enables the manufacture of products with simple structures. It is not suitable for machining products with complex geometries or complex components.

Since it can only be cut in three axes, the machining speed may also be slower than that of four- or five-axis CNC, as the workpiece may need to be manually repositioned to achieve the desired shape.

4-axis CNC machining

In four-axis CNC milling, a fourth axis is added to the movement of the cutting tool, allowing rotation around the x-axis. There are now four axes – X-axis, Y-axis, Z-axis, and A-axis (rotating around the x-axis). Most four-axis CNC machines also allow the workpiece to rotate, which is called the b-axis, so that the machine can act as both a milling machine and a lathe.

If you need to drill holes in the side of a part or on the curved surface of a cylinder, 4-axis CNC machining is the way to go. It greatly speeds up the machining process and has high machining accuracy.

5-axis CNC machining

Five-axis CNC milling has an additional axis of rotation compared to four-axis CNC. The fifth axis is rotation around the y-axis, also known as the b-axis. The workpiece can also be rotated on some machines, sometimes referred to as the B-axis or C-axis.

Due to the high versatility of 5-axis CNC machining, it is used to manufacture complex precision parts. For example, medical parts of artificial prosthetics or bones, aerospace parts, titanium parts, oil and gas machinery parts, military products, etc.

Although the advantages of five axes over four axes and three axes are very prominent, but not all products are suitable for five-axis machining, suitable for three-axis machining is not necessarily suitable for five-axis machining, if the original three-axis can process the product with five-axis processing, not only will increase the cost, the effect is not necessarily good. Only by reasonable arrangement and the development of suitable machine tools for the product can the value of the machine itself be brought into play.

What applications do we serve? Such as medical devices, robotics, oil&gas,automation, biotechnology, etc.

Still did not find a reliable machining supplier, contact us info@rymachining.com.