Jun. 28, 2025

Rollyu Precision Achieves NQA ISO 13485:2016 Certification: Raising the Bar for Medical-Grade Precision Manufacturing

In the world of precision manufacturing, quality isn’t just a box to tick—it’s the foundation of trust.

In June 2025, Rollyu Precision reached an important milestone: we officially earned ISO 13485:2016 certification from NQA.

This certification isn’t just a document on the wall. It’s a clear signal to every customer, supplier, and partner that we’re serious about meeting the highest standards of safety, consistency, and compliance, especially when it comes to medical devices.

Combined with our long-standing ISO 9001:2015 certification, this achievement gives our clients another layer of confidence: when you work with Rollyu, you’re working with a manufacturer that takes quality as seriously as you do.

This article will walk you through:

What ISO 13485:2016 is all about

Why it matters in medical and high-precision industries

How we’ve integrated ISO9001 and ISO13485 into a unified quality management system

What all this means for you as our customer

1. What is ISO 13485:2016?

ISO 13485:2016 is the international standard for quality management systems specific to medical devices.

In simple terms, it ensures that a manufacturer has everything in place to consistently deliver products that:

✅ Meet customer requirements

✅ Comply with applicable regulations

✅ Prioritize safety and performance at every stage

Compared to ISO9001, ISO13485 is more rigorous in a few key ways:

It requires a formal approach to risk management from start to finish

It demands clear, documented processes for design control and validation

It sets stricter rules for supplier management and material traceability

It puts a strong focus on recordkeeping and accountability

If your components are used in medical devices, life science equipment, or any critical system, this certification can make all the difference—especially when regulators or customers ask for evidence of compliance.

2. Why Did Rollyu Pursue ISO13485 Certification?

Over the past decade, Rollyu Precision has specialized in delivering high-precision machined and sheet metal parts to customers all over the world—industries like:

Medical equipment and surgical robotics

Dental systems

Life sciences and analytical devices

Automation and industrial robotics

Semiconductors and photonics

Through this experience, we’ve learned one important truth:

Precision is just the starting point. Reliability, compliance, and traceability are what earn long-term trust.

As medical device regulations around the world have tightened (think EU MDR, FDA QSR, and China’s NMPA), more and more customers now expect ISO13485 certification from their suppliers.

By achieving ISO13485 through NQA, we didn’t just check off a requirement—we reinforced our commitment to:

✅ Risk management

✅ Traceability

✅ Process validation

✅ Regulatory readiness

In other words, we’re ready to help you bring compliant products to market with less hassle and more confidence.

3. ISO9001 + ISO13485: A Powerful Combination

While ISO9001:2015 and ISO13485:2016 share a lot in common, they each bring something different to the table:

ISO9001:2015 | ISO13485:2016 | |

Who it’s for | All industries | Medical device manufacturers |

Main focus | Customer satisfaction, continual improvement | Product safety, compliance, risk control |

Risk management | General requirements | Mandatory, end-to-end |

Documentation | More flexibility | Very detailed records required |

Traceability | Recommended | Strictly enforced |

Design control | Basic | Extensive validation & verification |

At Rollyu, we built our ISO13485 system on top of our ISO9001 foundation. We:

✅ Reassessed and tightened our risk controls

✅ Strengthened supplier and materials oversight

✅ Enhanced process validation and documentation

✅ Invested in training so every employee understands their role in compliance

This means you don’t have to choose between flexibility and rigor—you get both.

4. Our Zero-Defect Commitment: The 6×100% Approach

At Rollyu Precision, “zero defect” isn’t a marketing phrase—it’s a mindset that guides our daily work.

Here’s how our 6×100% promise works:

1️⃣ 100% Incoming Materials Inspection

Every batch of material gets checked for:

Correct composition

Certification paperwork

Mechanical properties

Full traceability

2️⃣ 100% Dimension Achievement

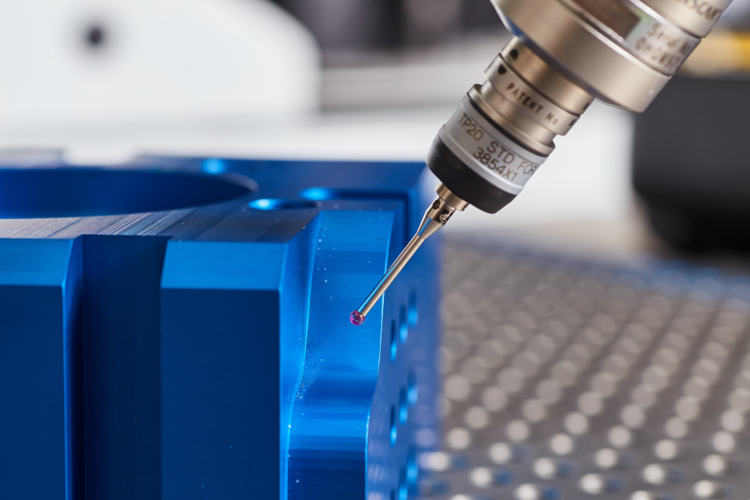

We measure every critical feature with calibrated tools like:

CMMs (Coordinate Measuring Machines)

Height gauges and micrometers

Thread gauges

Profile projectors

3️⃣ 100% Surface Finish Compliance

Whether it’s a medical housing or a photonics part, surface finish matters. We verify Ra values and appearance using dedicated roughness testers and visual inspection protocols.

4️⃣ 100% Pre-Shipment Inspection

Nothing leaves our facility without a final review of dimensions, labels, packaging, and documentation.

5️⃣ 100% On-Time Delivery

Our ERP production scheduling system keeps orders on track and transparent.

6️⃣ 100% Personalized Customer Support

Your project gets a dedicated point of contact who keeps you informed every step of the way.

5. Strict Production and Inspection Processes

To meet ISO13485 standards, we upgraded how we validate, document, and verify every step.