Nov. 20, 2025

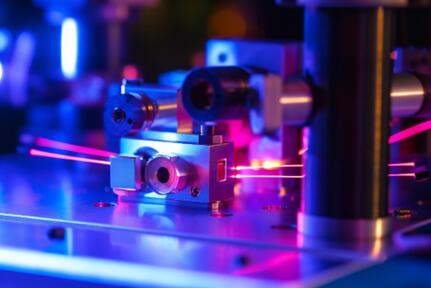

Photonics CNC Machining Parts – Advanced Components for Optical Innovation

Photonics systems demand components with nanometer-level accuracy. Whether you’re developing lidar sensors, quantum modules, high-speed fiber optics, or laser diagnostic systems, precision mechanical components are the foundation. At Rollyu Precision, we specialize in high-tolerance CNC machining for photonics OEMs—producing over 1,000 distinct components, from gripper brackets to alignment jigs, lens holders, diode nests, and custom stage carriages.

Our components are found in systems for laser steering, fiber coupling, light detection, and optical alignment—enabling breakthroughs in telecom, life sciences, aerospace, and AI sensing.

Photonics Hardware Demands Precision CNC Parts

Photonics components often serve optical paths, thermal management, or structural alignment—any imperfection affects performance. Rollyu delivers photonics CNC parts with:

Tight tolerances: ±0.005 mm or better

Mirror-finish surfaces: Ra < 0.2 µm

Thermal and vibration stability

Consistent fit for optomechanical systems

We routinely machine complex assemblies such as lens pods, collimator tubes, fiber clamp bases, optic head rings, and gonio stages, built to exacting tolerances in a temperature-controlled environment.

What We Machine for the Photonics Industry

We’ve delivered thousands of precision parts including:

➤ Optomechanical Assemblies

Lens holders, camera holders, diode holders, mirror brackets, mask holders, phosphor holders, LED ring supports

Collimator tubes, vortex holders, beam steering brackets, filter carriers, mirror glue links, laser diode holders

➤ Precision Positioning and Stages

Stage carriages, XY holder bases, gonio plates, eccentric shafts, pivot hubs, cleaver holders, scanner supports, alignment plates

Micrometer tips, mirror turrets, setup blocks, positioner mounts, gluing jigs, alignment pins, pneumatic cylinder supports

➤ Fiber Optics & Coupling Systems

Fiber holders, fiber fan-outs, fiber guides, fiber clamp bases, fiber gripper flexures, 230um/460um gripper jaws, loose tube adapters

Stripper base plates, fiber hook nests, lateral fiber guides, gripper columns, APD gripper assemblies.

➤ Mounts & Structural Supports

Manifolds, light supports, sensor housings, motor mounts, controller brackets, robot bases, inspection blocks, stage link braces

T-foot brackets, base gussets, angle supports, hinge shims, turret housings, microscope holders, clamp floors

➤ Laser System Parts

Laser clamps, cooling plates for life test lasers, laser hoods, beam delivery arms, excitation section covers, calibration blocks, induction plates

➤ Custom Fixtures & Carriers

Carrier thumbscrews, spool rack bases, demo lens jigs, prototype handles, glue brackets, mounting plates, mirror levelers, sensor flags

We also supply valve mounting plates, spring pushers, torch tips, cam rods, jaw holders, lock plates, pivoting screws, magnet holders, and more—supporting highly integrated assemblies where precision matters.

Materials Engineered for Optical Environments

We regularly machine:

Aluminum (6061, 7075) – black anodized for low reflectivity

Copper and BeCu – for heat transfer in diode modules

Titanium Grade 5 (Ti-6Al-4V) – ideal for weight-sensitive optical platforms

Stainless steels (304, 316, 17-4PH) – for structural rigidity

Plastics (PEEK, Ultem, Delrin, PTFE) – for electrical isolation, cleanroom compliance

Surface treatments include passivation, electropolishing, matte black anodizing, bead blasting, and optical masking for laser alignment protection.

Built-in Optical Precision Quality Control

To meet photonics-grade tolerances, Rollyu uses:

CMMs and laser interferometry for dimensional verification

Roughness testers for optical path components

Optical alignment validation for holders and plates

Thread and pin gauge certification for mounting interfaces

Material traceability & ISO 9001:2015 documentation

We support first article inspections (FAI), full batch certification, and customer-defined inspection protocols.

Who We Serve

Our components are used by:

Photonics startups developing laser-based diagnostics

Medical OEMs building diagnostic imaging systems

Lab and R&D groups prototyping custom mounts and optomechanics

Telecommunications – Fiber alignment tools, amplifier modules, scaling fiber optic networks ,and couplers

Medical Imaging & Diagnostics – Optical housings, fiber heads, and sensor mounts

Lidar and 3D Sensing – Compact enclosures and scanning modules

Laser Processing Systems – Beam collimators, alignment stages, and cooling blocks

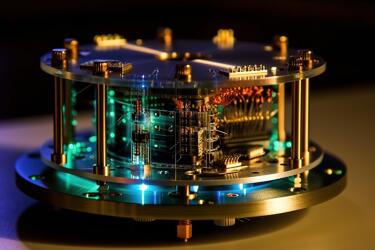

Quantum & Semiconductor Photonics – Precision frames and cavity parts for vacuum environments

Whether it’s a gripper support arm, carrier platform, microscope link, or prism holder, our team delivers high-mix, low-volume, and high-precision machining with short lead times.

Let’s Machine the Future of Light—Together

Your photonics hardware deserves more than generic machining. At Rollyu Precision, we specialize in the kind of parts others won’t touch: eccentric geometries, ultra-tight fits, and mission-critical assemblies.

Whether you need a diode jig, turret drive, sensor cradle, or an entire fiber optic subassembly, we are ready to collaborate—from CAD to cleanroom.

Contact us today info@rymachining.com to quote your project, review tolerances, or begin prototyping. Rollyu Precision—Where photonics meets perfection.