Mar. 02, 2023

And What are the benefits of the machining surface finishes?

Machining finishes are important processing in machining, and machining finishes can play an important role in protecting and beautifying the machining parts. In machining, there are various types of machining finishes, and when processing, it is necessary to make the correct selection of finishest types according to the material of the parts and the different processing requirements.

The common types of finishes in mechanical processing mainly include: electrostatic spraying, baking paint, galvanizing, chrome plating, nickel plating, titanium plating, gold plating, silver plating, aluminum anode, impregnation, powder coating, sandblasting, DLC treatment, Teflon treatment, black oxide, cold electroplating and so on. We introduce several common finish types and their functions.

1. Electrostatic spraying

Electrostatic spraying uses a high-voltage electrostatic field to orient the paint particles with a floating point in the opposite direction of the electric field to adsorb the paint particles on the surface of the machining parts.

Electrostatic spraying can obtain a thicker coating in one coating, powder coating solvent-free, and pollution-free, improving labor health conditions. Using new processes such as powder electrostatic spraying, the efficiency is high, it has good performance for automatic assembly line production; and can be recycled.

Initially used for protection and electrical convenience, it is now widely used in automotive processes, electrical insulation, corrosion-resistant valves, chemical pumps, castings, etc.

According to Rollyu Precision www.rymachining.com, you can apply this type of overlay to steel, stainless, aluminum, cast iron, copper, brass, bronze, zinc, and other materials.

2. Galvanized, chrome-plated, nickel-plated, titanium-plated, silver-plated

These finishes methods are coated with a metal film on the surface of the machining parts, in order to achieve the required purpose.

(1) Galvanizing: mainly to make the surface more beautiful.

(2) Chrome plating: can make metal products more durable, hard chrome plating is mainly used for machinery at high temperatures, such as: molds. Decorative chrome plating is mainly to make the surface more shiny and beautiful.

(3) Nickel plating: deposited on the metal surface by redox action, used to improve corrosion resistance and wear resistance, increase beauty and gloss.

(4) Titanium plating: prevent pollution, contact with the human body will not produce allergic reactions. Because titanium compounds come in a variety of colors, they can increase aesthetic effects. At the same time, titanium has the function of anti-acid, anti-alkali, and anti-oxidation.

(5) Silver plating: There are two main functions, one is decorative and the other is functional. Decorative properties are used to perform oxidation resistance tests. Functions are mainly used in the electronics industry, such as electrodes, wires, electric shock, and electrodes.

According to Rollyu Precision www.rymachining.com, you can apply this type of overlay to steel, stainless, aluminum, cast iron, copper, brass, bronze, zinc, and other materials.

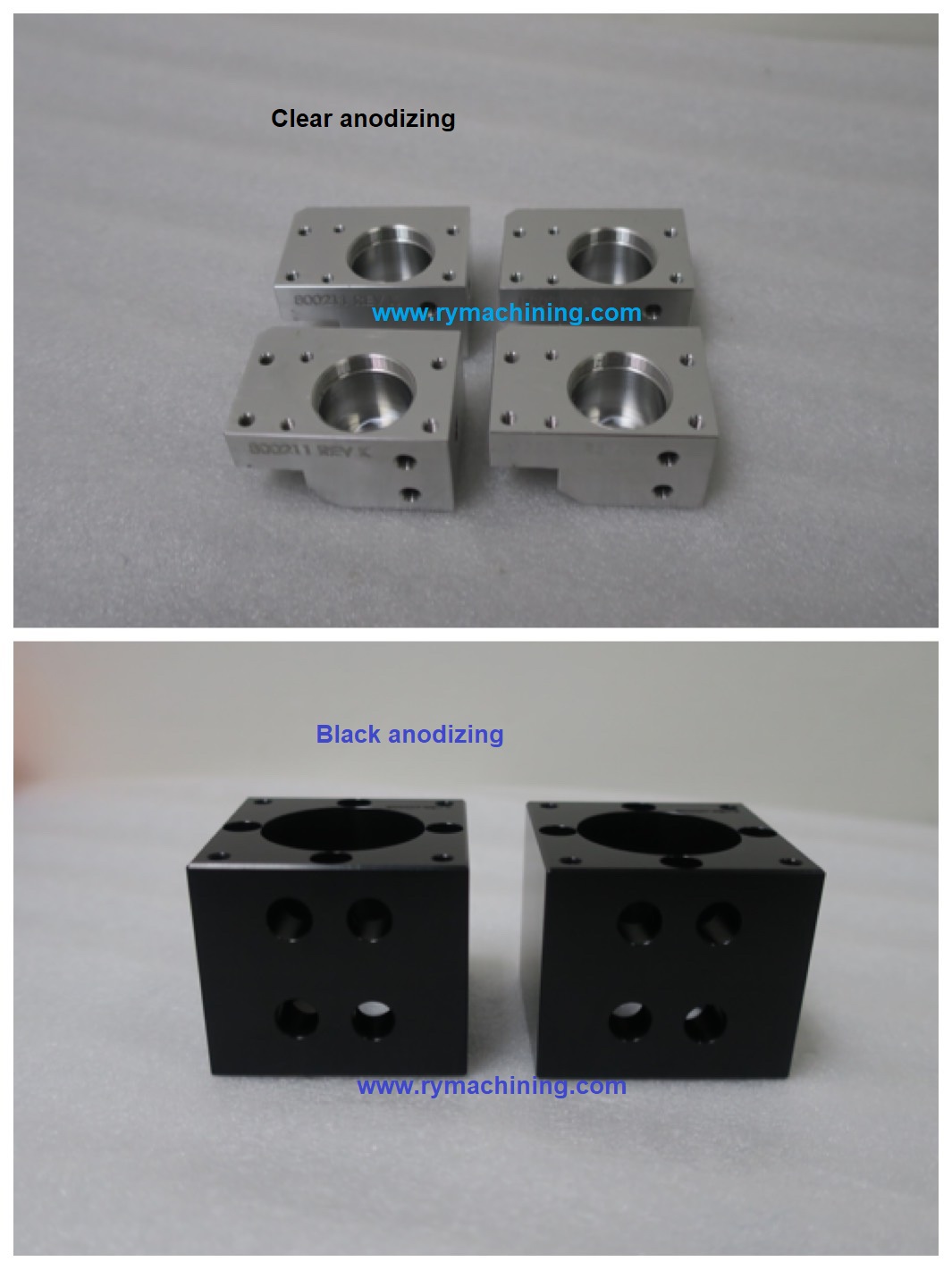

3. Aluminum anodized

Anodizing of aluminum is primarily a process of electrolytic oxidation, in which the surface of aluminum and aluminum alloys is usually transformed into an oxide film that has curing, decorative, and other functional properties.

The aluminum anode is mainly used in two aspects: one is when aluminum is used outdoors, and a protective film is formed on the surface of the aluminum after the anode, which can be protected from oxidation corrosion and prolong life. The second is used in electronics, so that the surface of the hard disk shell and radiator is not conductive, protecting the circuit and the human body.

According to Rollyu Precision www.rymachining.com, you can apply this type of finish to aluminum materials.

4. Black oxide

The black oxide process is a chemical conversion coating, it is an extremely thin (millionths of an inch) oxidation product created on the surface of a steel part; it has almost no corrosion resistance but it is attractive and does not affect the dimensions of parts; so it's used on things like bored sprockets, gears, and couplings, where dimensions are critical.

According to Rollyu Precision www.rymachining.com, you can apply this type of overlay to steel, stainless, aluminum, cast iron, copper, brass, bronze, zinc, and other materials.

5. Sandblasting

The compressed air dynamic force is formed to tell the spray beam to spray the spray material to the surface of the machining parts to be treated at high speed, so that the appearance of the machining parts surface changes. The effect of these finishes is to effectively improve the fatigue resistance of the machining parts, increase the adhesion between it and the coating, and extend the durability of the coating film.

According to Rollyu Precision www.rymachining.com, you can apply this type of finish to aluminum materials.

#electrostaticspraying, #bakingpaint, #galvanizing, #chromeplating, #nickelplating, #titaniumplating, #aluminumanode,#powdercoating, #sandblasting, #Teflon, #blackoxide, and so on. Which one do you like for your machining parts? Let's talk, send an email to info@rymachining.com.