Jan. 26, 2026

Hole Placement DFM for Sheet Metal Fabrication: How Proper Design Prevents Cracking, Distortion, and Rework

In precision sheet metal fabrication, hole placement isn’t just a small detail — it’s one of the most critical DFM (Design for Manufacturability) factors that determine whether your parts bend cleanly, assemble correctly, and maintain dimensional stability through production.

At Rollyu Precision, we routinely help customers resolve manufacturing challenges caused by poorly positioned holes. Without proper clearance to bends and edges, holes can distort, elongate, tear, or shift out of tolerance during forming — compromising both function and appearance.

This article will break down practical hole placement rules for sheet metal DFM that protect forming quality, improve yields, and stabilize production — especially for industries where precision is non-negotiable: medical devices, semiconductor equipment, robotics, aerospace, and telecommunications.

Why Hole Placement Is So Critical in Sheet Metal Forming

During bending, metal stretches and compresses along the bend line. Holes too close to these stressed regions will:

Distort shape: round holes become oval or elongated.

Shift position: hole centers move off location.

Crack edges: holes near edges may tear during forming.

Compromise threads: distorted holes create poor thread alignment for fasteners.

Cause cosmetic defects: visible deformities after coating or plating.

By applying simple DFM guidelines, most of these defects can be fully prevented — protecting both quality and cost.

Key DFM Rules for Hole Placement

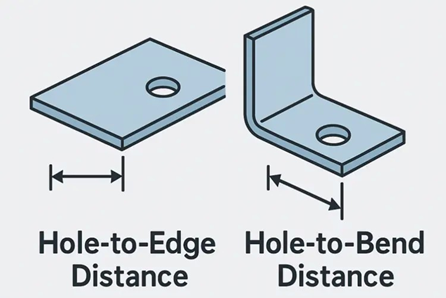

Design Rule | DFM Recommendation | Why It Matters |

Hole-to-Edge Distance | ≥ 2 × Material Thickness (2T) | Prevents edge tearing or weakening |

Hole-to-Bend Distance | ≥ 2 × Material Thickness (preferably 3T) | Prevents hole distortion during bending |

Hole-to-Hole Spacing | ≥ 2 × Material Thickness | Prevents material web thinning |

Minimum Hole Diameter | ≥ 1 × Material Thickness | Avoids punch distortion or tearing |

Multiple Holes Near Bends | Stagger holes further from bend | Minimizes distortion risk |

These guidelines assume standard 90° bends using CNC press brakes and air bending processes.

Visualizing Hole Distortion Near Bend Lines

Distance from Bend Line | Distortion Risk |

< 1T | Severe elongation or collapse |

1T | High risk of distortion |

2T | Minimal distortion |

3T | Nearly distortion-free forming |

✅ Rollyu Precision Pro Tip:

If functional holes must be near a bend, we often recommend adding those holes after forming through secondary machining or drilling.

Real-World DFM Case Study at Rollyu Precision

The Challenge:

A medical device OEM submitted a stainless steel sheet design for an electronic enclosure. Several mounting holes (M3) were placed just 0.5mm from a 90° bend line on 1.0mm thick stainless steel.

The Problems:

Holes distorted into ovals after bending.

Screw threads misaligned during assembly.

Cosmetic defects visible after powder coating.

High scrap rate due to failed inspections.

Rollyu Precision’s DFM Solution:

Relocated holes to 3.0mm (3T) from bend lines.

Confirmed stable forming through forming simulations.

Parts bent cleanly with zero hole distortion.

98% first-pass yield achieved in production.

Fully functional threads passed torque tests after plating.

Result: Small design adjustment = major cost and yield improvement.

Why Hole-to-Edge Distance Also Matters

While bending introduces distortion risks, edge proximity creates additional challenges:

Material tearing: Holes too close to edges may tear during punching.

Weakening structure: Thin edges may deform under fastening loads.

Plating defects: Thin metal near edges may create inconsistent coating.

Safe rule: Maintain hole centers at least 2T away from all edges.

The Hidden Cost of Poor Hole Placement

Ignoring DFM hole placement rules leads to:

Increased scrap and rework

Cosmetic rejects after coating

Expensive secondary operations (reaming, drilling, reshaping)

Delays in production due to non-conforming parts

Assembly line problems due to fit-up issues

Early DFM review eliminates these costs before production begins.

How Rollyu Precision Supports DFM for Hole Placement

At Rollyu Precision, hole placement is fully integrated into our design review process:

✅ Early DFM feedback on customer CAD files

✅ Simulation of bend behavior near holes

✅ Recommendations to optimize hole spacing and sequencing

✅ Secondary machining strategies for unavoidable close-to-bend holes

✅ Prototyping to verify stability before production launch

Our DFM support helps customers avoid common forming mistakes and achieve stable, repeatable production runs — even for complex medical, semiconductor, and aerospace assemblies.

Industries That Require Tight Hole Placement Control

Medical Device Enclosures

Semiconductor Shielding Components

Robotics and Automation Brackets

Aerospace Sensor Mounts

Telecommunications Chassis

Photonics and Optical Device Frames

In these industries, hole distortion is not simply cosmetic — it directly affects product function, assembly fit, and downstream regulatory compliance.

Optimize Hole Placement, Protect Production Stability

Hole placement may seem minor — but poor hole location can easily compromise your entire sheet metal fabrication process.

At Rollyu Precision, our DFM-first approach helps customers:

Eliminate hole distortion

Improve first-pass yield

Prevent forming failures

Ensure stable cosmetic finishes

Reduce costly secondary operations

✅ Small DFM adjustments during design reviews create long-term production success.

Hole placement issues are far easier—and far less expensive—to correct during design than after forming or finishing.

If you would like a DFM review of your sheet metal design, or need engineering feedback on hole-to-bend and hole-to-edge placement, our team is ready to support you early in development.

Previous: None